01

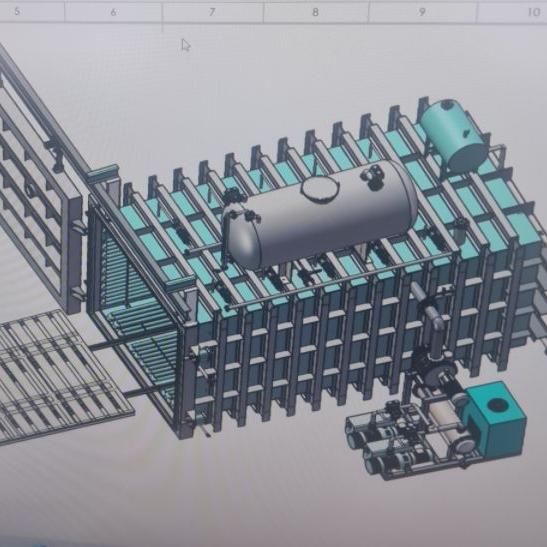

Vacuum Drying Oiling Equipment

Ihlanganisa isipiliyoni esicebile senkampani yethu ekukhiqizeni i-transformer kanye nobuchwepheshe obuqoqiwe kulo mkhakha.

Ikakhulukazi isetshenziselwa ukomisa nokugcoba ama-transformer acwiliswe ngamafutha, ama-amorphous alloy transformers, ama-reactors, nama-capacitor.

Phakathi nenqubo yokomisa, okokusebenza ngokuqhubekayo kushintsha ukucindezela ethangini lokomisa ukuze kuqinisekiswe ukuthi umkhiqizo ushisisa ngokulinganayo, ususa umswakama ohwamukile ngesikhathi esifanele, futhi uvimbela umgogodla wensimbi ekugqwaleni. Indlela yokomisa eqhubekayo inciphisa ukuwohloka komkhiqizo futhi iqinisekisa ukomiswa ngokuphelele.

Imishini inesakhiwo nenqubo efanele. Uma kuqhathaniswa nezindlela zendabuko zokumisa i-vacuum, isikhathi sokumisa sincishiswa cishe ngama-30-45%. Kuyimishini ethembekile, ephumelelayo neyonga amandla enesistimu yokugcwalisa uwoyela othomathikhi ngokugcwele, futhi ukulungiselelwa kwevolumu kawoyela kuyashesha futhi kulula. Sihlinzeka ngobuchwepheshe be-transformer yokomisa nokwelashwa kokugcwalisa uwoyela kwemikhiqizo kagesi kuma-transformer amandla acwiliswe uwoyela angaphansi kuka-35KV (ongakukhetha okungu-35KV no-10KV).

Izici eziyinhloko zobuchwepheshe zemishini: Izinto ezisetshenziswayo zinesistimu yokukhipha i-vacuum eklanywe ngokucophelela, futhi amanzi anele ajiyile akhululwa ku-condenser enezinga lokushisa eliphansi, eligwema ngokuphumelelayo ukungcoliswa komswakama wepompo ye-vacuum phakathi nenqubo yokomisa.

Ngesikhathi senqubo yokushisa, ingcindezi ethangini le-vacuum iyancipha ibe yinani elithile ngokusho komjikelezo wokushisa womkhiqizo, okwenza izimo ezifanele kakhulu zokuhwamuka kwamanzi kungqimba lokufakwa komkhiqizo futhi kuqinisekiswe ubuhlakani benqubo yokuhwamuka ngesikhathi. inqubo yokushisisa. inqubo omiswe.

Ngesikhathi senqubo yokushisa, ingcindezi ethangini le-vacuum iyancipha ibe yinani elithile ngokusho komjikelezo wokushisa womkhiqizo, okwenza izimo ezifanele kakhulu zokuhwamuka kwamanzi kungqimba lokufakwa komkhiqizo futhi kuqinisekiswe ubuhlakani benqubo yokuhwamuka ngesikhathi. inqubo yokushisisa. inqubo omiswe.

Izinto ezisetshenziswayo zilungiswa ngokuya ngenqubo yokomisa ingcindezi, kuxazululwe ngempumelelo inkinga yokugqwala kwensimbi phakathi nenqubo yokomisa. Izinga lokuzenzakalela kwemishini kanye nobuchwepheshe bokucubungula sekufinyelele emazingeni athuthukile asekhaya, okuqinisekisa ukuthi ikhwalithi yomkhiqizo isezingeni eliphambili embonini.

Inqubo yokugcwalisa uwoyela yenziwa ngaphansi kwe-vacuum egcwele, futhi uwoyela ugcwaliswa ngokuzenzekelayo futhi ngokunembile ngemva kokumisa ukuze kuqinisekiswe ikhwalithi yomkhiqizo ethembekile.

Izinto zokusebenza zamukela isistimu yephampu ye-vacuum enezigaba ezintathu, enethangi elingenalutho ekugcineni kwe-vacuum engu-50Pa kanye nezinga lokuvuza elingu-≤0.5mbar·l/s, eliqinisekisa ukuhlanzeka okuphezulu nendawo evacuum ephezulu.

Umqoqi wokuhlukanisa uwoyela negesi ufakwa phakathi kweyunithi ye-vacuum kanye nethangi le-vacuum ukuze kuncishiswe futhi kubuyiselwe ingxenye kawoyela we-insulating, ngaleyo ndlela kuncishiswe futhi kunciphise ukungcoliswa kwesistimu ye-vacuum ngamafutha avikelayo.

Iminyango yokumisa i-vacuum kanye ne-oiling tank kanye nama-flange e-tank lid akhiqizwa ngokuya ngamazinga we-vacuum imishini ukuqinisekisa ukuqina kwama-flanges.

Wonke amapayipi omjovo kawoyela kanye nezinsiza zenziwa ngensimbi engagqwali engu-304.

Inombolo efanelekile yamapayipi egatsha omjovo kawoyela ingena ethangini lomjovo kawoyela ngama-flange.

Iqembu ngalinye lamapayipi egatsha lingaxhunywa emkhiqizweni ngokusebenzisa amapayipi afanele ukuze kube lula uwoyela wokuvikela ofanelekayo ukuze ungene emkhiqizweni.

Isistimu yomjovo kawoyela ifakwe imitha yokugeleza ye-turbine, esetshenziselwa ukusetha kusengaphambili inani lomjovo kawoyela wegatsha ngalinye. Lapho inani lomjovo kawoyela osethiwe lifinyelelwa, ivalvu yokufaka uwoyela iyavaleka.

Igatsha ngalinye liphinde lifakwe i-valve yokulawula insimbi engenasici ukuze ilawule ukugeleza komjovo kawoyela, ngaleyo ndlela ilawule ijubane lomjovo kawoyela.

Uhlelo lokulawula olusezingeni eliphezulu lisebenzisa i-Siemens PLC njengeyunithi yokulawula eyinhloko, futhi uhlelo lokusebenza lungakwazi ukubona ukulawula okuzenzakalelayo kokuhlanza nokugcwalisa uwoyela phakathi nenqubo.

Kubandakanya imiyalo ye-alamu yokushisa ngokweqile, ukuvikela okuzenzakalelayo kokunqamuka kwegesi, ukwaziswa kwe-alamu, njll.

Imishini ingumnyango owodwa onemisebenzi yokugcwalisa i-vacuum kanye nowoyela, futhi isisindo esiphezulu singafinyelela ku-30T ekusebenzeni okukodwa.

Ngaphansi kwezimo ze-vacuum, i-valve yokugcwalisa uwoyela eyodwa ingasetshenziselwa ukufeza ukugcwaliswa kwamafutha okuzenzakalelayo okuzenzakalelayo noma ukugcwaliswa kwamafutha okwenziwa ngesandla.

Ukusebenza kwemishini kulawulwa izinkinobho kuphaneli yokulawula, okuhlanganisa ukushintshwa kweminyango, ukuhlanza, ukugcwalisa uwoyela okwenziwa ngesandla/okuzenzakalelayo, njll., futhi kufakwe amadivayisi aphelele okuvikela ukuphepha.

Ikhaya

Ikhaya