Lokhu kuqeda izinguquko zezimpawu ngesikhathi sokusonga. Ngaphezu kwalokho, umshini ubuye ufakwe idivayisi yezinzwa zokulungisa. Isebenzisa izinzwa ze-photoelectric ezingathinteki ukuze ithole noma yikuphi ukuchezuka onqenqemeni lwe-foil futhi ikulungise ngendlela eguquguqukayo kusetshenziswa indlela yokulungisa ukuchezuka eshayelwa yi-servo. Isistimu inokunemba okuphezulu, ukuphendula okuphezulu, nokuthembeka okuphezulu, futhi ukunemba kokulungiswa kungaphakathi kuka-+/-0.4mm. Amakhoyili enziwe ngocwecwe alinyazwa ngamaphepha ethusi ne-aluminium anogqinsi oluhlukene njengamakhondatha, izinto zokuvikela ezibanzi njenge-interlayer insulation, kanye nezinto ezivikelayo eziwumngcingo njenge-insulation end. Amakhoyili akhiwa ngenqubo eyodwa yokusonta emshinini wokusonta we-foil one-voltage ephezulu.

Umshini uphinde uqedele ukushiselwa komkhondo wangaphakathi nangaphandle wekhoyili, kanye nokuvunguza kwendawo yangaphandle. Ngokusebenza kwawo okuphelele, umshini unikeza ukwesekwa okwanele kokukhiqiza ama-foil rolls ekucacisweni okudingekayo. Sekuyithuluzi elibalulekile lokukhiqiza izingxenye zemikhiqizo enjalo kagesi. Ukutshala imali emshinini wokuvunguza we-foil we-voltage ephezulu kuqinisekisa izinqubo zokukhiqiza eziphumelelayo, ukukhiqizwa kwamakhoyili wekhwalithi ephezulu kanye nokwenza kahle okuphelele kokusebenza kokukhiqiza i-transformer.

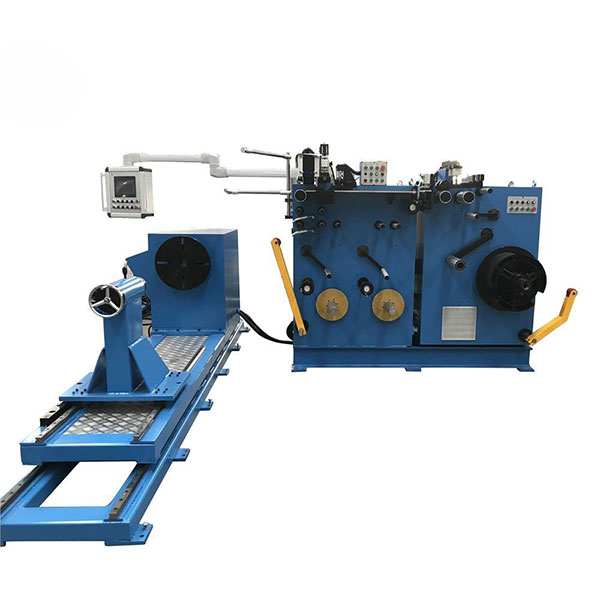

Imishini yokugcwalisa i-foil ene-voltage ephezulu

ukunemba nokusebenza kahle ekukhiqizeni ikhoyili Umshini wokusonta we-foil we-voltage ephezulu uyisisetshenziswa esinembayo esiklanyelwe ngokukhethekile ukuhlangabezana nezidingo zokukhiqiza ikhoyili yamandla kagesi aphezulu. Iqukethe izingxenye ezibalulekile ezimbalwa ezisebenza ndawonye ukuze kuqinisekiswe ukuphenduka okunembile kanye nekhwalithi ephezulu yekhoyili.

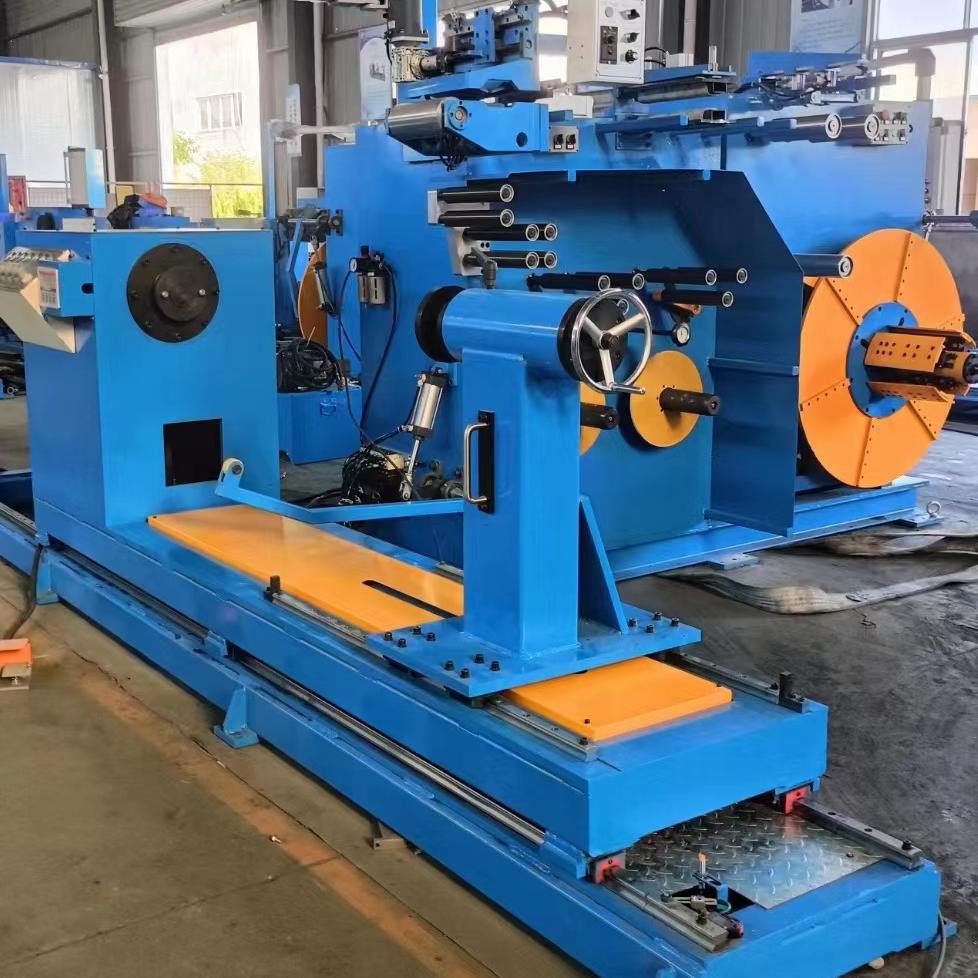

I-aluminiyamu ye-foil uncoiler

I-unwinder isekela ukuvuleka, ukuqoqwa kanye nokukhishwa kwamapheshana e-aluminium foil. Ine-spindle eyindilinga enezixhumanisi ezine ezibamba amabhulokhi amane anwebekayo, okuvumela isigubhu ukuthi sisekelwe kusigubhu esilayishayo ngezisekelo ze-hydraulic. I-servo motor enamandla amakhulu ishayela i-spindle ukuze ikhulule ngokunembile, ikhiphe, futhi ihlehlise emuva, ikuvumela ukuthi ulungise izimo zokusebenza ngokushesha nakalula. Lo mklamo uqinisekisa ukuthi ukuchezuka kwe-tension kuhlala njalo ngaphakathi kwebanga elincane phakathi nenqubo yokusonta. Amasethi amabili emishini yokuzwa ukumanzisa okuzimele ahlanganiswe emshinini wokuvula umoya, onganikeza ububanzi obubanzi bokulungiswa kokuqina.

Idivayisi yokudambisa ithatha isilawuli se-pneumatic ukuhlinzeka ngokucindezela njalo komsebenzi we-servo motor, elula, ehlanzekile futhi ephephile ukuyilawula. Yonke i-decoiler ixhunywe ku-fuselage ngokusebenzisa imigqa emikhulu yokuqondisa futhi ifakwe uhlelo lokulungisa i-servo. Ngaphansi komyalelo wesistimu yokulawula ye-PLC futhi ngokusekelwe empendulweni yesignali yokuthola ukuchezuka, umshini wokuvula umoya uhamba ngokunembile eduze nomzila wesitimela ukuze ulungise indawo yefoyili ukuze uqinisekise ukuma okunembile nokulungiswa kokuchezuka kwefoyili.

Isistimu yokuphefumula

Umshini wokusonga utholakala ekugcineni kwemishini futhi ugoqa itheyiphu ye-foil eduze kwe-shaft ephendukayo. Beka kuqala amandla omshini kanye ne-torque ephumayo ekwakhiweni komshini wokusonga, ucabangela ubukhulu bobukhulu bezinto zokusebenza kanye namandla okunweba adingwa yinqubo. Igobolondo langaphandle lomshini osongayo lishiselwe ngamapuleti ensimbi awugqinsi futhi acutshungulwe ngemva kokwelashwa kwe-anneal kanye nokunciphisa ingcindezi.

I-gear system ye-transmission kanye ne-gearbox iqukethe ama-helical-module amakhulu, amaphrofayili wezinyo aqiniswe kusetshenziswa ubuchwepheshe bokugaya. Lokhu kuqinisekisa amandla emishini ekuphumeni kwetorque ephezulu, kuqinisekisa ukusebenza okushelelayo kanye namazinga aphansi omsindo wawo wonke amathuluzi.

Umshini usebenzisa ukulawulwa kwejubane lokuvama okuguquguqukayo ukuze unikeze i-torque ephezulu kanye nesivinini sokujikeleza esifanele ngesivinini esiphansi. Inikeza i-torque eyanele kanye nesivinini esiphezulu ukuze kuhlangatshezwane nezidingo zezinqubo ezihlukene zokusonta. Phakathi nenqubo yokusonta okuphothayo, imithambeka yokusheshisa yokuqala nokumisa isethwe ngokufanelekile, futhi inomsebenzi wokubhuleka ukuze kuthuthukiswe ukutholakala kokusebenza. Isebenzisa i-high-power drive motor futhi inendathane yokugcina amandla.

Uhlelo lokunyakaza lwesokunxele/kwesokudla: Ukunyakaza kwesobunxele/kwesokudla komshini wokusonga kufezwa ngesistimu ye-servo motor kanye nesinciphisi seplanethi esinembayo.

Lesi simiso siqinisekisa ukuchezuka okukhulu kwamasethi amabili wamakhoyili ngesikhathi sokuphenduka nokunyakaza.

Amandla okuzivocavoca angahlelwa kusengaphambili ngesikrini esithintwayo futhi avulwe ngezinkinobho ukuze asebenze kalula.

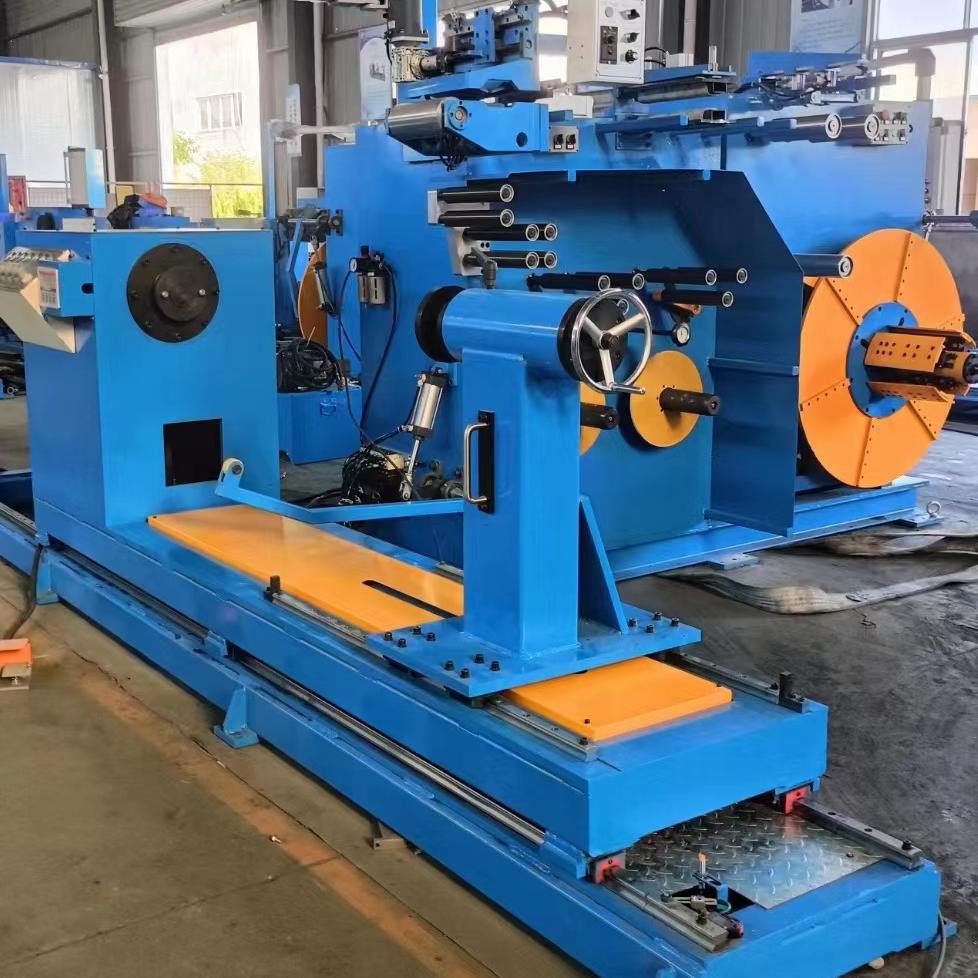

Isistimu yokuphefumula

Idivayisi yesendlalelo evikelayo: Idivaysi yokuqaqa isendlalelo sokuvala isekela ukusonteka kwento ebambayo futhi iqinisekisa ukunwetshwa kwayo phakathi nenqubo yokusonga. Umshini onama-winding ufakwe amasethi amabili wezindlela zokuqeda ukufakwa kwe-insulation, ezingahlinzeka ngezingqimba ezimbili zephepha lokufaka i-insulation noma ifilimu yokushisa ukushisa ngesikhathi esisodwa. Umshini unezingxenye ezine: irola yokulayisha evuthekayo, isistimu yokushayela, irola ye-insulation layer guide, kanye nomshini wokudambisa. Ngokucindezela i-valve yomoya ekugcineni kwesigubhu esiphefumulayo, ibhulokhi yokunweba yenjoloba iyahoxisa, okuvumela okokusebenza ukuthi kufakwe ngqo esigubhu. Sebenzisa isibhamu somoya ukuze ukhulule ibhulokhi yokukhulisa irabha ngevalvu yomoya ukuze ulungise futhi uvuthele ikhoyili evalekile futhi ugcine isimo sokukhulisa esidingekayo ngesikhathi sokusonga. I-tension ingalungiswa kalula futhi ngokuzenzakalelayo ngokusebenzisa i-guide roller kanye ne-damping roller. Isistimu yamandla yedivayisi yokususa umoya yokufaka i-insulation isebenzisa i-servo motor enembayo futhi inobubanzi obubanzi bokulungiswa kokuqina. Amandla omshini wokudambisa alawulwa ukungeniswa kwe-pneumatic, okuthumela iziyalezo ku-servo motor ukuze ibone umsebenzi wokushuba njalo. Lo mklamo uqinisekisa ukulawula okulula, ukuhlanza, ukuphepha nokuzungezisa okubuyisela emuva ukuze kube lula kakhulu.

Idivayisi yokukhipha imali

Le divayisi yokukhipha iwasusa ngempumelelo ama-burrs kumateyipu e-foil ngokulawula umfutho womoya otholakala kumasethi amabili amarola anembayo. Le nqubo ayisusi ama-burrs kahle kuphela, kodwa futhi inikeza ukunyakaza okuguquguqukayo okuhlukahlukene kuhlaka olubambe amarola anembayo. Lokhu kungalungiswa ngokuvumelana nobukhulu, ububanzi kanye nokungahleliwe kwetheyiphu, ngokuphumelelayo ukunciphisa ama-burrs emaphethelweni e-aluminium foil tape. Umfutho womoya ungabuye ulungiswe ngokungahleliwe ngokuhambisana nobukhulu be-foil, ikakhulukazi ezintweni eziwugqinsi, kunciphisa kakhulu ingozi yokulahlwa kwezinto ezibonakalayo ngesikhathi senqubo yokusonta.

Ukuqothula kuyinqubo ebucayi engeke ishaywe indiva, ngoba ama-burrs angalashiwe noma angahlanzekile angase abhoboze iphepha le-insulating, libangele amasekhethi amafushane noma ngisho nemililo. Izinkampani eziningi zikugcizelele ukubaluleka kwalesi sici.

Qaphela

Idizayini eyingqayizivele - idivayisi yokuqeda ukungcola ixhunywe kusikhumuli se-uncoiler futhi inganyakaza ivundlile ukuze inciphise ukuwohloka nokumelana lapho kunxeshezelwa ukuchezuka kweteyiphu. Lokhu kuqinisekisa ukuqondanisa okunembile komkhiqizo, kususa ngokuphumelelayo ukungcola ebusweni be-aluminium foil, futhi kuthuthukisa ukuzinza kwekhwalithi yomkhiqizo.

Idivayisi yokushisela okuzenzakalelayo: Le divayisi yokushisela ihlangabezana nezidingo zokushisela zamapheshana we-foil nemikhondo.

Ukwamukela i-lap welding, imihlathi ye-welding fixture ingashwibeka ngezinga elithile.

Umhlathi ongezansi ungafaka umfutho obheke phezulu futhi imihlathi ingashintshwa njengoba kudingeka. I-clamp yesistimu yokushisela ifakwe ku-fuselage, futhi isibhamu sokushisela, uhlelo lokuhamba oluzenzakalelayo, ne-clamp ingahamba kwesokunxele nakwesokudla ku-clamp. Kodwa-ke, uma inqubo yokushisela isiqediwe, umshini wokushisela ubuyela emuva kwesokunxele, udedele indawo yokusonta ukuze usebenze kalula.

Isibhamu sokushisela sifakwe ku-trolley ehambayo futhi singalungiswa ezindaweni ezahlukene ukuze sivumelane namafomu ahlukahlukene wokushisela. I-trolley ehambayo ishayelwa yi-motor speed eguquguqukayo, i-reducer ne-screw. Isivinini se-Welding singashintshwa kalula. Le ndlela yokushisela isebenzisa i-alternating current ne-direct current ye-argon arc welding (TIG) ngaphandle kwesidingo sezinto zokugcwalisa.

Isistimu yokulawula ye-elekthronikhi: Isistimu yokulawula ye-elekthronikhi inikeza imiyalelo yezinto ezihlukahlukene zokukhiqiza, ezifana nokujikajika, ukulungiswa kokuchezuka, ukubala imilenze nezibonisi ezihlukahlukene, ngokusekelwe ekubalweni kwesistimu yokulawula ye-PLC ngokusebenzisa izinhlelo zethu zemithombo yobunikazi kanye nezinqubo zokusebenza. Ukuqaliswa kwezinhlelo ezihlukahlukene kuqinisekisiwe. Ama-opharetha adinga kuphela ukufaka amapharamitha asebenzayo afanele ngesixhumi esibonakalayo se-HMI esikhulu sesikrini sokuthinta ukuze baqedele kalula ukukhiqizwa kwenqwaba yezinto zokusebenza ezinezincazelo ezifanayo.

Zonke izinto zokusebenza zingase futhi zisetshenziswe ngesandla ngokusebenzisa izinkinobho zokulawula, okuhlanganisa ukusebenza ngokushesha nokusebenza kokuxhumanisa. Kunezinkinobho eziningi zezimo eziphuthumayo kuphaneli yokulawula eyinhloko namathuluzi amakhulu. Uma izimo ezingavamile zenzeka, isistimu ingavalwa ngesikhathi ukuze kuqinisekiswe ukuphepha.

Yonke imisebenzi yohlelo ingenziwa nge-universal console. Uhlelo lwe-pneumatic: Uhlelo lusebenzisa ukulawula okuphakathi nendawo kanye nezithulisi eziningi ukuze kuqinisekiswe ukuthi izinga lomsindo wawo wonke umshini liphansi kunemishini efanayo engenisiwe. Ukucindezela kanye nezinga lokugeleza kwegatsha ngalinye kungalungiswa ngokuzimela. Ukwenziwa kwesenzo somoya ngasinye kulawulwa uhlelo lwe-PLC.

Ikhaya

Ikhaya