01

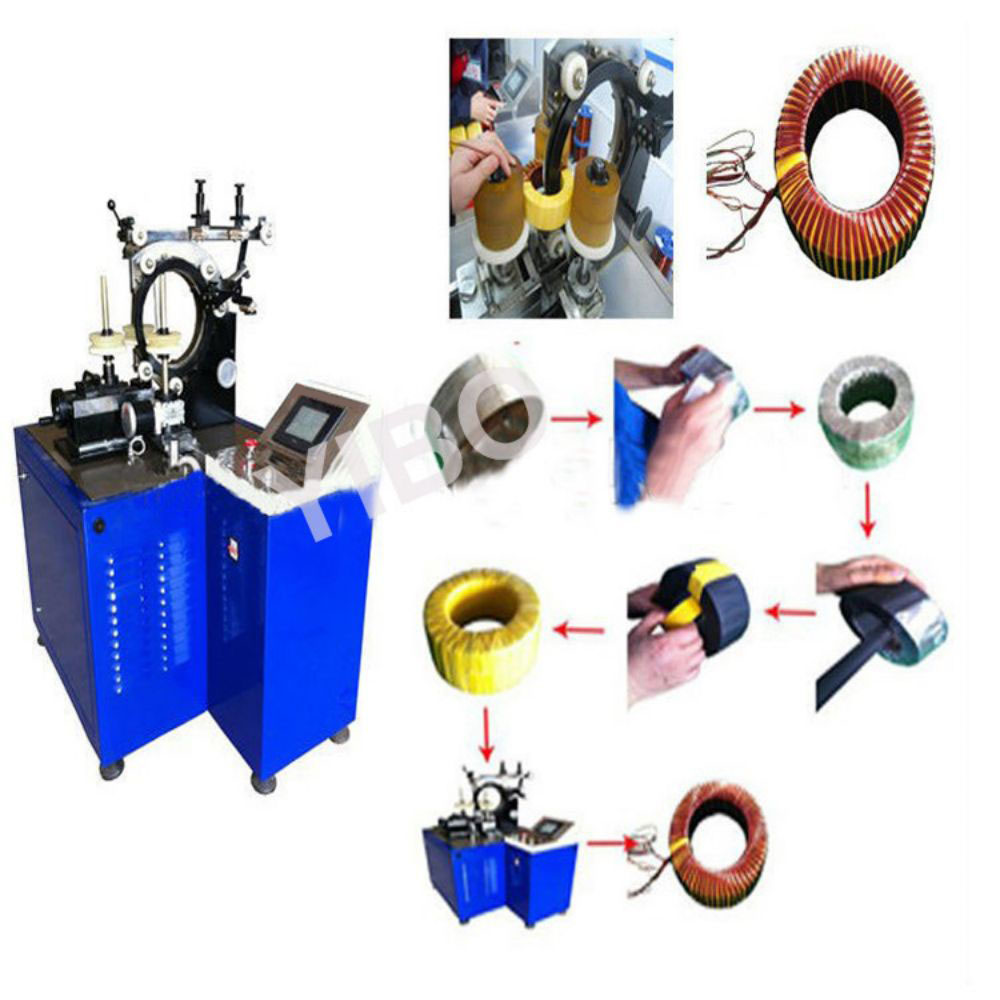

Umatshini wokujija wenxeba ophambili we-toroidal

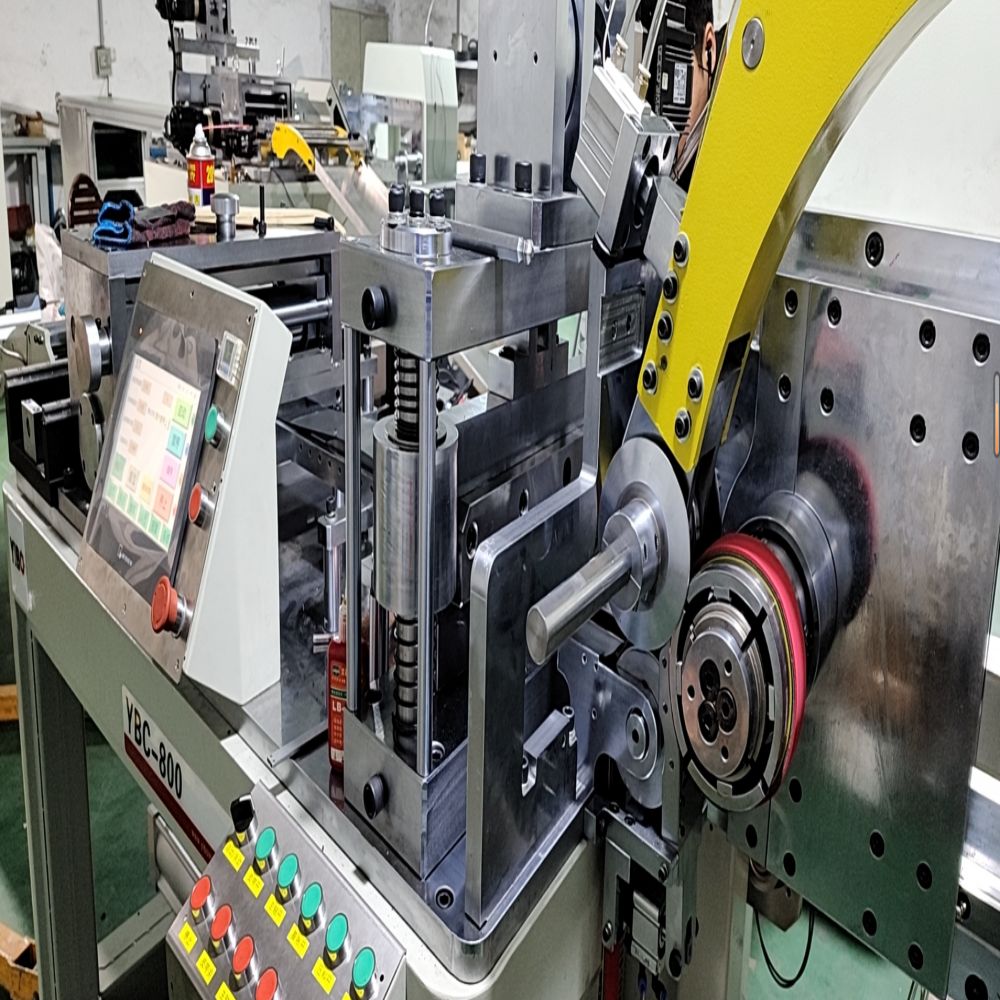

Umatshini uxhotyiswe ngenkqubo yamva nje yekhompyuter kunye neteknoloji ye-servo drive ukulawula inkqubo entsonkothileyo yokutya, ukusika kunye nokubuyisela umva. Inamandla okusebenza abanzi, ivumela ububanzi bomcu ukuya kuthi ga kwi-250 mm kunye nokufikelela kwidayamitha engundoqo yangaphandle eyi-800 mm. Umatshini ubonelela ngenkqubo yokuvelisa eguquguqukayo kakhulu, echanekileyo kunye nethembekileyo yokuhambisa abaguquli. Idibanisa iingenelo zendalo zeteknoloji yenxeba, njengelahleko ephantsi kakhulu, ukudibanisa ngokukhawuleza kunye nomthamo ophezulu xa kuthelekiswa notyalo-mali olufunekayo.

Iimpawu eziphambili

Ukusebenza ngokuzenzekelayo ngokuzenzekelayo: Umatshini ugqiba ngokuzenzekelayo iinkqubo zokutya, ukukhokela, ukujika, ukujika, kunye nokusika ngaphandle kokungenelela ngesandla, ukuphucula kakhulu ukusebenza kwemveliso.

Inkqubo yokulawula ye-Siemens yaseJamani kunye ne-HMI touch screen: Umatshini uxhotyiswe ngenkqubo yokulawula ye-Siemens kunye ne-interface yomsebenzisi-friendly HMI touch screen. Olu kudibanisa luqinisekisa isantya esiphezulu sekhompyutheni, ukusebenza okunamandla kunye nokulula ukusebenza, ukulawula imveliso engenamthungo. Imveliso engundoqo ye-toroidal esebenzayo: Umatshini unako ukuvelisa i-gap cores esasazwayo kunye ne-toroidal cores ukuhlangabezana neemfuno ezahlukeneyo zoshishino kunye nokusetyenziswa.

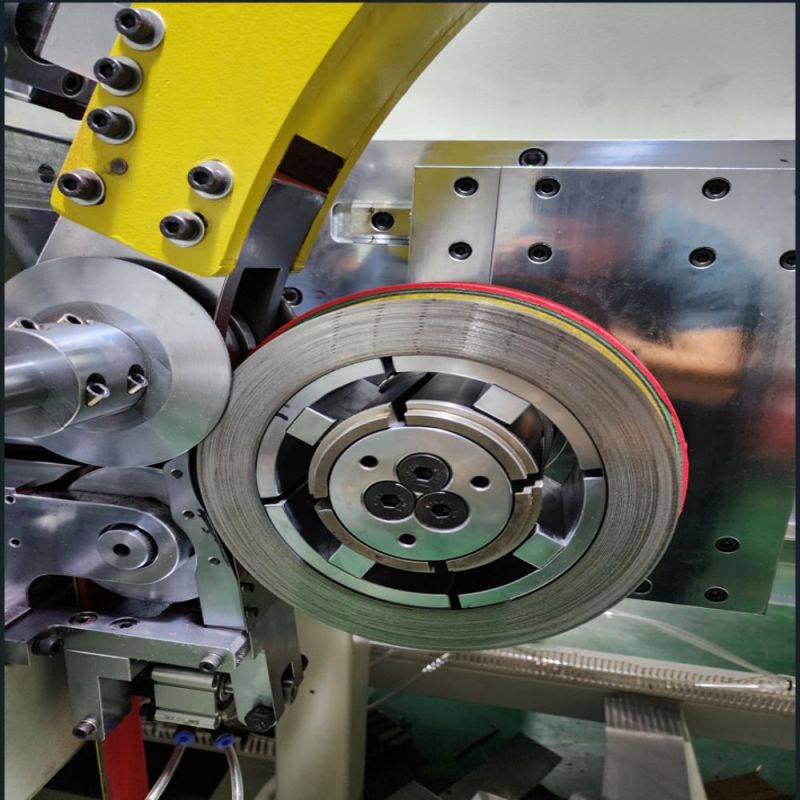

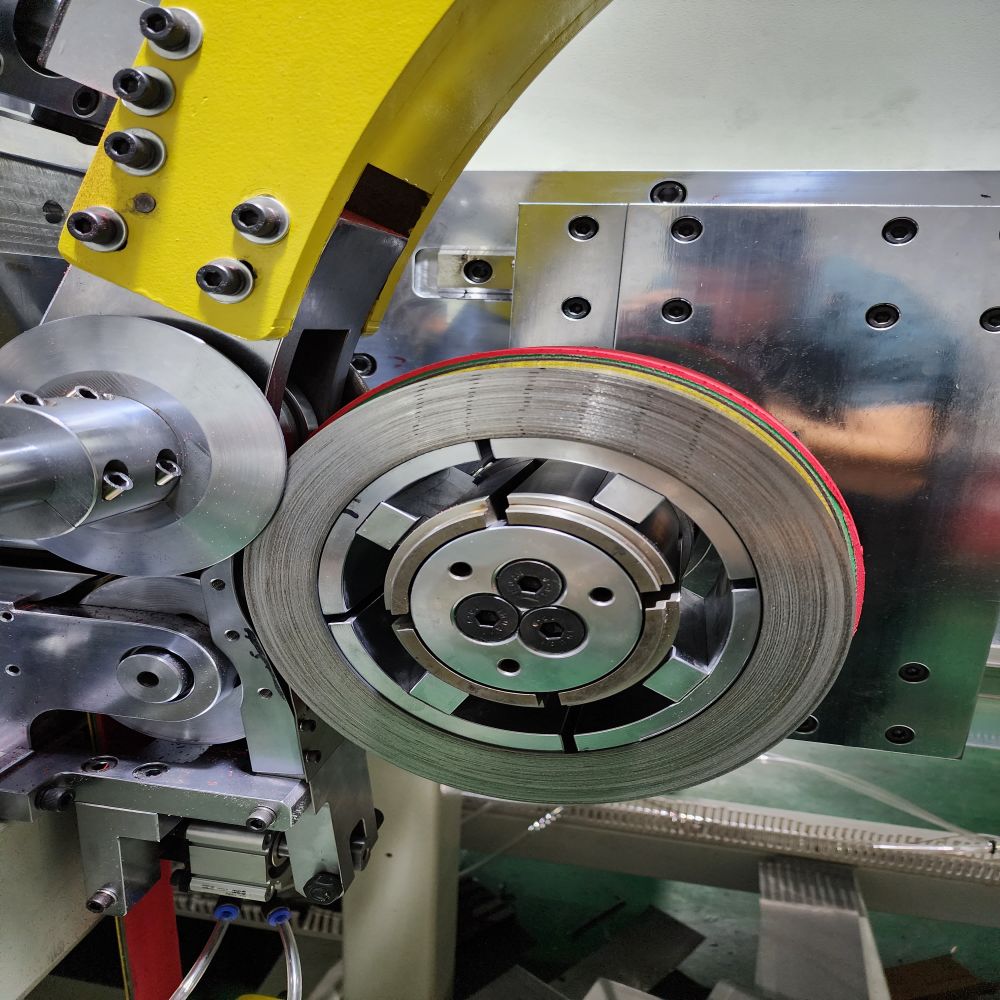

Amanyathelo alungelelaniswayo ngokuthe nkqo: Umatshini unako ukulungelelanisa amanyathelo amileyo ukusuka kwi-2 ukuya kwi-15 ukulungiselela ukucwangciswa kweendlela ezahlukeneyo zokujika. Isigaba ngasinye sinokuthatha i-1 ukuya kwi-3 yamaphepha angundoqo, ukubonelela ukuguquguquka okukhulu kunye nokulungelelaniswa kweemfuno ezahlukeneyo zokujija.

Ubungakanani begesi obuhlengahlengiswayo kunye nesantya sokutya: Abaqhubi banokuhlengahlengisa ngokulula ubungakanani begesi kunye nesantya sokutya ngokusebenzisa i-HMI-friendly interface yesikrini sokuthinta isikrini, ukuqinisekisa ulawulo oluchanekileyo lwenkqubo yokuvelisa.

Itekhnoloji yokujija ngokuzenzekelayo: Ukwamkelwa kwetekhnoloji yokupakisha ezenzekelayo kunciphisa kakhulu iimfuno zabasebenzi kunye nokunciphisa iimpazamo, ngaloo ndlela kwandisa imveliso kunye nomgangatho wemveliso.

Ukuqina okuphuculweyo: Umatshini uxhotyiswe ngeyunithi yokusika insimbi ye-tungsten eqinisekisa ukuqina okuphuculweyo kunye nobomi benkonzo nangona usebenza phantsi kweemeko ezinzima.

Amacandelo omgangatho ophezulu: Umatshini usebenzisa amacandelo akumgangatho ophezulu, kubandakanywa amacandelo e-pneumatic yaseJapan SMC kunye nezixhobo zombane zaseYurophu kunye neJapan. Isebenzisa ii-motor ze-Siemens ze-servo zaseJamani, izinciphisi ze-servo ezithunyelwa kumazwe angaphandle, izikhokelo zemigca, kunye neebheringi zokuqinisekisa ukusebenza kakuhle kunye nokuthembeka.

Ngomatshini wokujija wenxeba ongundoqo we-toroidal, unokufezekisa ukuchaneka okuphezulu kunye nokusebenza kakuhle. Imisebenzi yayo ephezulu, ukusebenza okuzenzekelayo kunye nobuchule bemveliso obuguquguqukayo buyenza ibe sisixhobo esiyimfuneko kwimveliso engundoqo yamanxeba kumashishini ahlukeneyo.

Ekhaya

Ekhaya