01

Thepa e phahameng ea vacuum impregnation bakeng sa ho tlatsa thepa hantle

Thepa ea rona e phahameng ea vacuum impregnation e fana ka ho kenngoa ka mokhoa o nepahetseng le o nepahetseng oa graphite ho sebelisa mefuta e sa tšoaneng ea metsi, ho kenyelletsa le sekontiri. Ts'ebetso e ntlafatsa thepa ea thepa, e e lumella hore e sebetse ka mokhoa o tsitsitseng lits'ebetsong tse kang li-electrode, litiiso le likaroloana tse tlotsitsoeng.

Hlahisa Impregnation

Ka lisebelisoa tsa rona, lihlahisoa tsa cast li kenngoa hantle ka epoxy resin, ho netefatsa hore likheo li tletse ka botlalo. Sena se eketsa matla a mochine, se fokotsa porosity le ho eketsa ho hanyetsa maemo a tikoloho, e leng se hlahisang lihlahisoa tsa boleng bo phahameng.

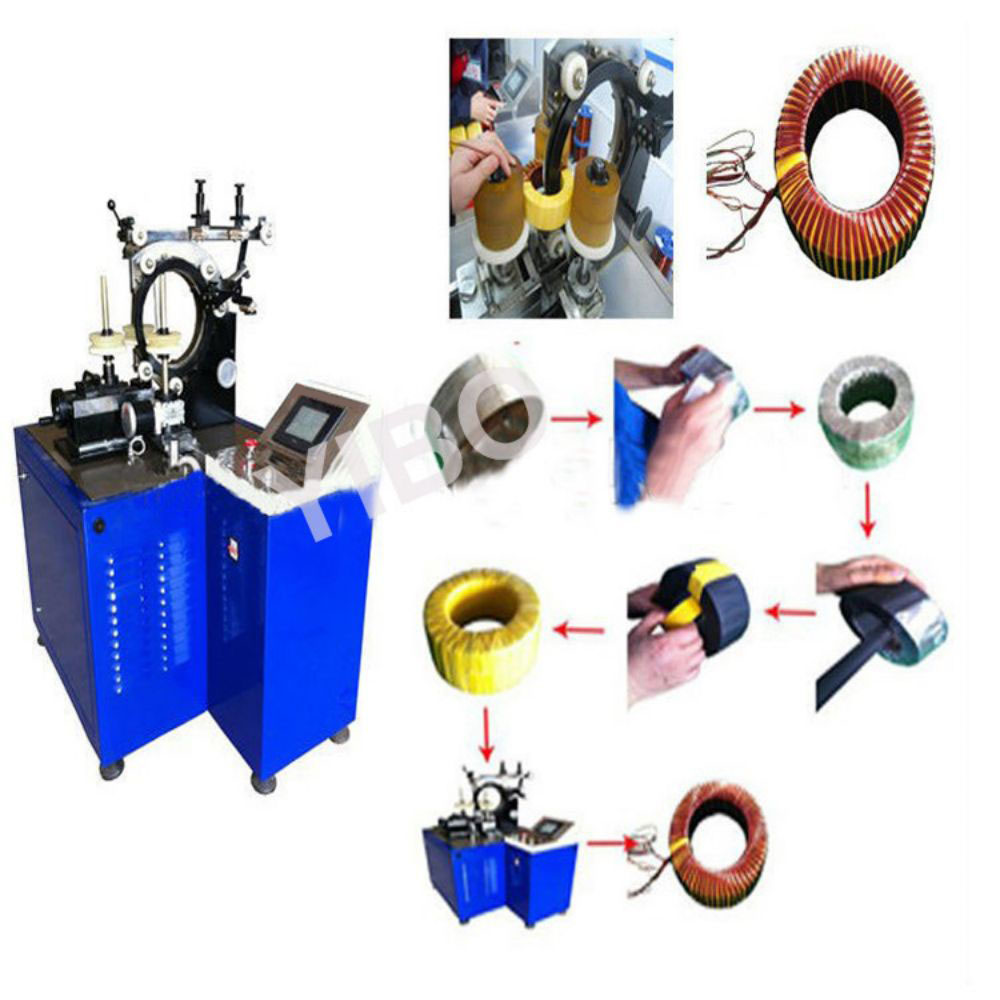

Motlakase oa li-coil le motsoako oa likarolo: Lisebelisoa tsa rona li etselitsoe ho phekola li-coil tsa motlakase le likaroloana.

Ka ho kenya lekhalo ka varnish e sireletsang, likarolo li fumana matla a phahameng a dielectric, ho ntlafatsa conductivity ea mocheso le khanyetso e kholo ea ho senyeha ha motlakase, ho netefatsa ts'ebetso e ka tšeptjoang.

Likopo tse Tloaelehileng

Thepa ea rona ea ho kenya khatello e phahameng ea vacuum e ka hlophisoa ho fihlela litlhoko tse ikhethang tsa liindasteri tse fapaneng. Ho tloha ho mekhahlelo ea ts'ebetso ea motho ka mong ho ea ho litekanyo tse ikhethileng tsa kamore, re fana ka tharollo bakeng sa litlhoko tse ikhethileng, ho netefatsa ts'ebetso e nepahetseng le tlhahiso.

Melemo ea lihlahisoa

Lisebelisoa tsa rona li fana ka vacuum e phahameng nakong ea ts'ebetso ea ho kenya letsoho, ho tlosa moea le mongobo ka katleho sehlahisoa. Sena se lumella mokelikeli o kenyang letsoho hore o kene hantle ka har'a likheo, kahoo o eketsa ho tlala ha thepa le ho ntlafatsa ts'ebetso ea sehlahisoa.

Boleng bo tsitsitseng

Thepa ea rona e tšehelitsoe ke sehlopha se nang le boiphihlelo sa baenjiniere ba nang le boiphihlelo ba lilemo tse fetang 20, ba netefatsang boleng bo tsitsitseng le bo tsitsitseng ba ho inregnation. Karolo e 'ngoe le e' ngoe ho tloha ho moralo ho isa ho tlhahiso e etsoa ka hloko ho netefatsa liphetho tse tšepahalang le tsa boleng bo holimo bakeng sa bareki ba rona.

PLC e laola ka ho feletseng

Thepa ea rona e nka PLC taolo e ikemetseng ka botlalo, e ka fihlelang taolo e nepahetseng le e nepahetseng ea ho kenella. Sena se felisa phoso ea motho, se tiisa ts'ebetso ea ts'ebetso ea ho emola, 'me se fokotsa kotsi ea bofokoli ba lihlahisoa, e leng se bakang ts'ebetso e eketsehileng le ho boloka litšenyehelo.

Motho ka mong

Rea utloisisa hore moreki e mong le e mong o na le litlhoko tse ikhethang. Lisebelisoa tsa rona li fana ka likhetho tsa motho ka mong ho fihlela litlhoko tsa motho ka mong.

Ho tloha lits'ebetsong tse feto-fetohang ho isa ho meralo e bonolo ea likamore, re fana ka litharollo tse ikhethileng ho fihlela litlhoko tse ikhethang tsa kopo.

Likarolo: Ho kenngoa ha khatello ea vacuum ho etsa hore ho be le tšitiso e sebetsang hantle le e phethahetseng

Baenjiniere ba nang le phihlelo ba fana ka tiiso ea boleng bo tsitsitseng le e tsitsitseng

PLC e laola ka botlalo, ts'ebetso e nepahetseng le e se nang liphoso

Likhetho tse ikhethileng tsa motho ka mong bakeng sa ts'ebetso e nepahetseng le tlhahiso Tsetela ho lisebelisoa tsa rona tsa khatello e phahameng ea vacuum le ho ntlafatsa ts'ebetso ea ho kenya tšebetsong indastering ea hau.

Rua molemo ho theknoloji ea rona e phahameng ea vacuum, tiisetso e tsitsitseng ea boleng, lienjineri tse nang le boiphihlelo, taolo ea PLC e itirisang ka botlalo le likhetho tsa motho ka mong ho fihlela boleng bo holimo ba thepa le ho ntlafatsa ts'ebetso ea sehlahisoa sa hau.

Lehae

Lehae