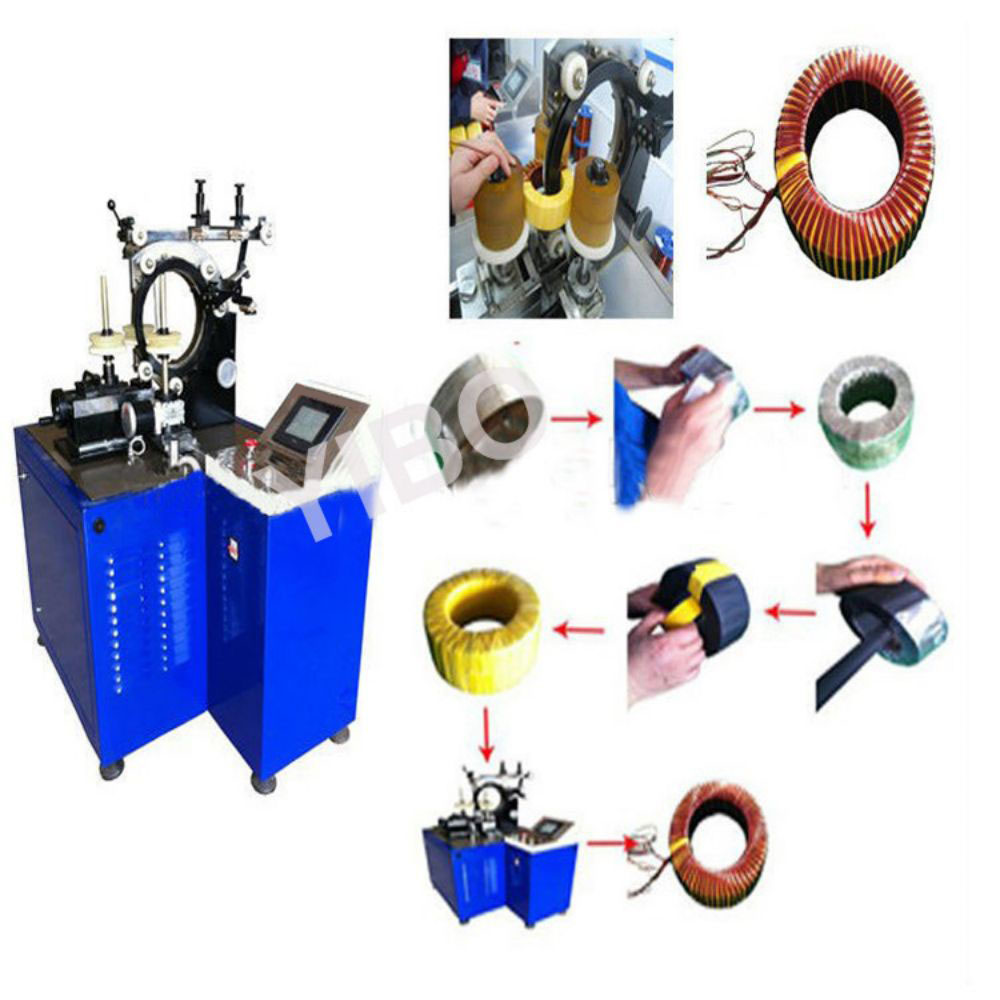

Izvi zvinobvisa kuchinja kwechisimbiso panguva yemhepo. Uye zvakare, muchina uyu zvakare wakashongedzerwa nekugadzirisa sensor mudziyo. Inoshandisa isingabatanidzi photoelectric sensors kuona chero kutsauka pafoil mupendero uye nekuigadzirisa zvine simba kuburikidza ne-servo-inotyairwa kutsauka kwekugadzirisa magadzirirwo. Iyo sisitimu ine hupamhi hwepamusoro, kupindura kwepamusoro, uye kuvimbika kwepamusoro, uye iko kururamisa kuri mukati me +/-0.4mm. Mafoiri makoiri anokuvadzwa nemhangura nearuminiyamu mapeiri ehukobvu hwakasiyana semakondukita, yakafara insulating zvinhu se interlayer insulation, uye nhete insulating zvinhu semagumo ekudzivirira. Makoiri anoumbwa kuburikidza neimwe nzira yekumonereka pane yakakwirira-voltage foil mhepo muchina.

Muchina wacho unopedzisawo kusungirirwa kwemukati nekunze kunotungamira kwecoil, pamwe nekuputika kwekunze kwekunze. Nekushanda kwayo kwakazara, muchina uyu unopa rutsigiro rwakakwana rwekugadzira foil rolls kune zvinodiwa. Yakava midziyo yakakosha yekugadzira zvikamu zvezvigadzirwa zvemagetsi zvakadaro. Kuisa mari mumuchina wepamusoro-voltage foil winding machine inogonesa maitiro ekugadzira, emhando yepamusoro-coil kugadzira uye optimization yakazara yetransformer kugadzirwa kwemabasa.

High-voltage foil winding machines

kunyatsoita uye kunyatsoita mukugadzira coil Yakakwira-voltage foil mhepo yekuisa muchina ndeye chaiyo dhizaini yakagadzirirwa kusangana nezvinodiwa zvepamusoro-voltage coil kugadzirwa. Iyo ine akati wandei makiyi zvikamu zvinoshanda pamwe chete kuti ive nechokwadi chekunyatso mhepo uye chepamusoro coil mhando.

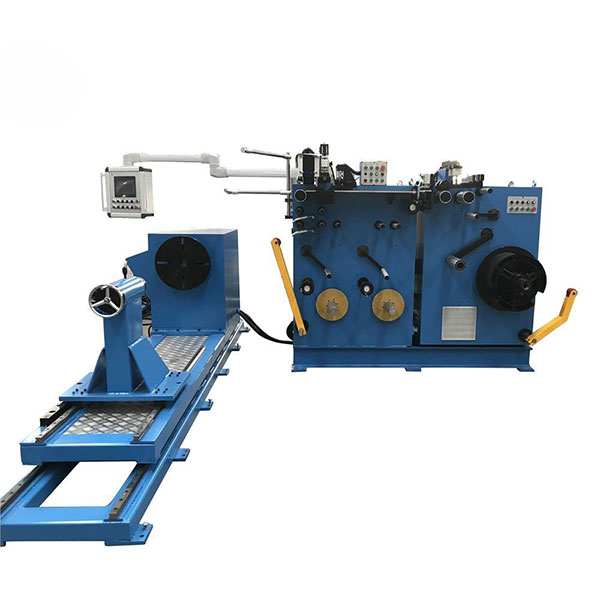

Aluminium foil uncoiler

Iyo unwinder inotsigira kusunungura, kuunganidza uye kuburitswa kwealuminium foil mitsetse. Iyo ine denderedzwa inotenderera ine mana link inobata zvidhinha zvina zvinokwidziridzwa, zvichibvumira chigubhu kuti chitsigirwe padhiramu rekurodha kuburikidza ne hydraulic inotsigira. Iyo yepamusoro-simba servo mota inotyaira iyo spindle kuti inyatso kusunungura, kuburitsa, uye kudzosera kumashure, ichikutendera iwe kugadzirisa mamiriro ekushanda nekukurumidza uye nyore. Iyi dhizaini inovimbisa kuti tension kutsauswa kunogara mukati meiyo diki renji panguva yekuita mamhepo. Maseti maviri ezvishandiso akazvimirira ekunyorovesa sensing akabatanidzwa mumuchina wekusunungura, uyo unogona kupa huwandu hwakasiyana hwekugadzirisa tension.

Iyo yekunyorovesa mudziyo inotora pneumatic control kuti ipe inogara ichinetsekana basa reiyo servo mota, iri nyore, yakachena uye yakachengeteka kudzora. Iyo yese decoiler yakabatana kune fuselage kuburikidza nehombe mutsara njanji uye ine servo kugadzirisa system. Pasi pekuraira kwePLC control system uye zvichibva pamhinduro yechiratidzo chekutsauka, muchina wekusunungura unofamba nemazvo uchitevedza gwara renjanji kuti ugadzirise nzvimbo yefoil kuti ive nechokwadi chekumisikidzwa uye kutsauka kururamisa kwefoiri.

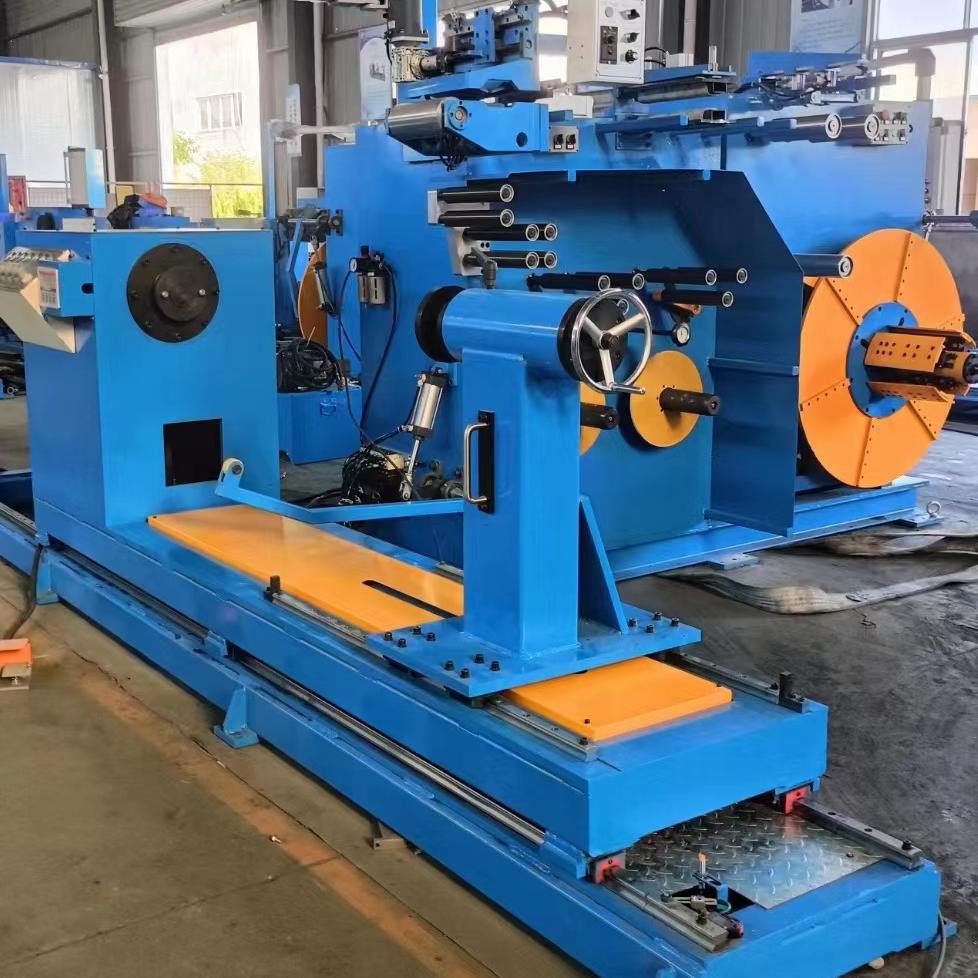

Winding system

Muchina wekupeta unowanikwa kumucheto wepamberi wemidziyo uye unoputira tepi yefoil kutenderedza shaft inotenderedza. Isa pamberi pesimba remagetsi uye torque yekubuda mukugadzirwa kwemuchina wekupeta, uchifunga nezvehukuru hwehukuru hwechigadzirwa chebasa uye simba rekuwedzera rinodiwa nemaitiro. Iyo goko rekunze remuchina unomonereka rakasungirirwa nemarata esimbi gobvu uye rinogadziriswa mushure mekuvhara uye kurapwa kwekunetsekana.

Iyo giya sisitimu yekutapurirana uye giya bhokisi rine hombe-module helical magiya, iwo mazino profiles ayo akaomeswa nekushandisa kugaya tekinoroji. Izvi zvinogonesa simba remakanika pane yakakwira torque kubuda, kuve nechokwadi chekushanda kwakatsetseka uye yakaderera ruzha mazinga emidziyo yese.

Muchina uyu unotora inosiyana frequency kumhanyisa regulation kuti ipe yakanyanya torque uye yakakodzera kutenderera kumhanya pakumhanya kwakaderera. Inopa torque yakakwana uye yakanyanya kumhanya kuti isangane nezvinodiwa zveakasiyana mhepo maitiro. Munguva yekutenderedza mhepo, yekutanga uye kumisa kukwirisa materu akaiswa nenzira kwayo, uye ine braking basa rekuvandudza kuwanikwa kwekushanda. Iyo inotora yakakwirira-simba dhiraivha mota uye ine akawanda simba rekuchengetedza.

Kuruboshwe / kurudyi kufamba sisitimu: Kufamba kwekuruboshwe / kurudyi kwemuchina unomonereka kunowanikwa kuburikidza ne servo mota system uye chaiyo inoderedza mapuraneti.

Iyi sisitimu inovimbisa kutsauka kwakanyanya kwemaseti maviri emakoiri panguva yemhepo uye kufamba.

Kusimba kwekurovedza muviri kunogona kugadzikwa kuburikidza nekubata skrini uye kuvhurwa nemabhatani kuitira nyore kushanda.

Winding system

Insulating layer mudziyo: Iyo insulation layer yekusunungura mudziyo inotsigira kupepeta kweiyo insulation zvinhu uye inova nechokwadi chekuwedzera kwayo panguva yekupepeta. Muchina wekupeta wakashongedzerwa nemaseti maviri ekudzivirira kusunungura masisitimu, ayo anogona kupa maviri akaturikidzana emapepa ekudzivirira kana kupisa kupisa firimu panguva imwe chete. Iyo meshini ine zvikamu zvina: inflatable loading roller, yekutyaira system, insulation layer guide roller, uye damping device. Nekudzvanya vharuvhu yemhepo pamagumo edhiramu inoputika, iyo rubber yekuwedzera block inodzosera, ichibvumira kuti zvinhu zvipinzwe zvakananga mudhiramu. Shandisa pfuti yemhepo kuti usunungure rubber ekuwedzera block kuburikidza nemhepo valve kugadzirisa uye inflate iyo insulated coil uye kuchengetedza inodiwa yekuwedzera mamiriro panguva yemhepo. Iko kushushikana kunogona kugadziridzwa zviri nyore uye zvisina tsarukano kuburikidza negidhi roller uye damping roller. Iyo yemagetsi sisitimu yekuvharisa unwinding mudziyo inotora chaiyo servo mota uye ine yakafara tension gadziriso renji. Simba remudziyo wekunyorovesa rinodzorwa nepneumatic induction, iyo inotumira mirairo kune servo mota kuti ione iyo inogara ichinetsa basa. Iyi dhizaini inovimbisa kutonga kuri nyore, kucheneswa, kuchengetedzwa uye kudzoreredzwa kutenderera kwekuwedzera kuve nyore.

Deburring mudziyo

Ichi chidhinha chinobvisa zvinobudirira kubvisa maburrs kubva pamatepi efoiri nekudzora kudzvanywa kwemhepo kunoitwa pamaseti maviri emaroller chaiwo. Maitiro aya haangobvisi maburrs zvakanaka, asi zvakare anopa anochinja-chinja oscillating mafambiro kune furemu inobata iwo chaiwo rollers. Izvi zvinogona kugadziridzwa zvichienderana nehupamhi, hupamhi uye kusagadzikana kwe tepi, zvinobudirira kuderedza mabhura pamipendero yealuminium foil tepi. Kudzvanywa kwemhepo kunogonawo kugadziridzwa zvisina tsarukano zvichienderana nekukora kwefoiri, kunyanya kune zvakakora zvinhu, zvichideredza zvakanyanya njodzi yekuraswa kwezvinhu panguva yekupepeta.

Kubvisa inzira yakaoma isingagone kufuratirwa, nekuti mabhura asina kucheneswa kana asina kuchena anogona kubaya bepa rekudzivirira, zvichikonzera mapfupi maseketi kana moto. Makambani mazhinji akasimbisa kukosha kwechinhu ichi.

Cherechedza

Yakasarudzika dhizaini - iyo decontamination mudziyo yakabatana kune uncoiler uye inogona kufamba yakachinjika kuti ideredze deformation uye kuramba kana uchibhadhara kutsauka kwetepi. Izvi zvinogonesa kurongeka chaiko kwechigadzirwa, zvinonyatso bvisa tsvina pamusoro peiyo aluminium foil, uye inosimudzira kugadzikana kwemhando yechigadzirwa.

Otomatiki welding mudziyo: Ichi chishandiso chewelding chinosangana nezvinodiwa zvewelding zvefoil mitsetse uye inotungamira.

Kugadzirisa lap welding, shaya dzeiyo welding fixture dzinogona kuzununguka kune imwe nhanho.

Rushaya rwezasi runogona kuisa kukwira kumusoro uye shaya dzinogona kutsiviwa sezvinodiwa. Iyo yekusungirira yewelding system yakaiswa pane fuselage, uye pfuti yekubatira, otomatiki yekufamba sisitimu, uye clamp inogona kufamba kuruboshwe uye kurudyi pane clamp. Nekudaro, kana iyo welding process yapera, iyo welding mechanism inodzokera kuruboshwe, ichisunungura chinzvimbo chemhepo kuti ishande nyore.

Pfuti yewelding yakaiswa pane trolley inofambiswa uye inogona kugadziridzwa kune dzakasiyana siyana kuti ienderane kune akasiyana siyana welding mafomu. Iyo trolley inofambisa inotyairwa neinosiyana yekumhanyisa mota, inoderedza uye screw. Welding speed inogona kugadziriswa nyore nyore. Iyi nzira yewelding inoshandisa alternating ikozvino uye yakananga ikozvino kune argon arc welding (TIG) pasina kudiwa kwezvinhu zvekuzadza.

Electronic control system: Iyo yemagetsi control system inopa mirairo yezvinhu zvakasiyana-siyana zvekugadzira, senge mhepo, kutsauka kugadzirisa, kuverenga kwemakumbo uye akasiyana maratidziro, zvichibva pakuverenga kwePLC control system nekushandisa yedu proprietary source zvirongwa uye maitiro ekushanda. Kuitwa kwemaitiro akasiyana-siyana kunovimbiswa. Vashandi vanongoda kuisa maparamendi anoshanda kuburikidza neiyo hombe yekubata screen HMI interface kuti ipedze nyore kugadzirwa kwakawanda kwemaworkpiece ane zvakafanana zvakatemwa.

Midziyo yese inogona zvakare kushandiswa nemaoko kuburikidza nemabhatani ekudzora, kusanganisira nekukasira kushanda uye yekubatanidza kushanda. Kune akawanda mabhatani ekukurumidzira pane main control panel uye mikuru michina. Kana mamiriro asina kujairika aitika, sisitimu inogona kuvharwa nenguva kuti ive nechokwadi chekuchengetedza.

Kwese mashandiro eiyo system anogona kuitwa kuburikidza neuniversal console. Pneumatic system: Iyo sisitimu inotora modular centralized control uye akawanda silencers kuti ive nechokwadi chekuti ruzha rwemuchina wese wakadzikira pane yakafanana midziyo inotengeswa kunze kwenyika. Kudzvinyirirwa uye kuyerera kwebazi rimwe nerimwe kunogona kugadziriswa zvakasununguka. Kuitwa kwega rega pneumatic chiito kunodzorwa nePLC chirongwa.

Kumba

Kumba