Ibi bikuraho impinduka zidodo mugihe cyo kuzunguruka. Mubyongeyeho, imashini nayo ifite ibikoresho byo gukosora. Ikoresha ibyuma bifata ibyuma bifata ibyuma bifata amashanyarazi kugirango ibone gutandukana kuruhande rwa fayili kandi irabikosora muburyo bukoreshwa na servo itwarwa na devis yo gukosora. Sisitemu ifite ibisobanuro bihanitse, byitabirwa cyane, kandi byizewe cyane, kandi gukosora neza biri muri +/- 0.4mm. Igiceri gifunitse gikomerekejwe numuringa na aluminiyumu yubunini butandukanye nkuyobora, ibikoresho bigari byerekana ko ari interineti, hamwe n’ibikoresho bigufi bikingira. Ibishishwa bikozwe muburyo bumwe bwo kuzunguruka kuri mashini ihinduranya amashanyarazi menshi.

Imashini irangiza kandi gusudira imbere ninyuma yimbere ya coil, kimwe no kuzunguruka hejuru yinyuma. Hamwe nimikorere yuzuye, imashini itanga inkunga ihagije yo gukora ibizunguruka bisabwa. Byahindutse ibikoresho byingenzi byo gukora ibice byibicuruzwa byamashanyarazi. Gushora imari mumashanyarazi yumuvuduko mwinshi utanga umusaruro ushimishije, gukora ibicuruzwa byiza byujuje ubuziranenge hamwe no kunoza imikorere yibikorwa bya transformateur.

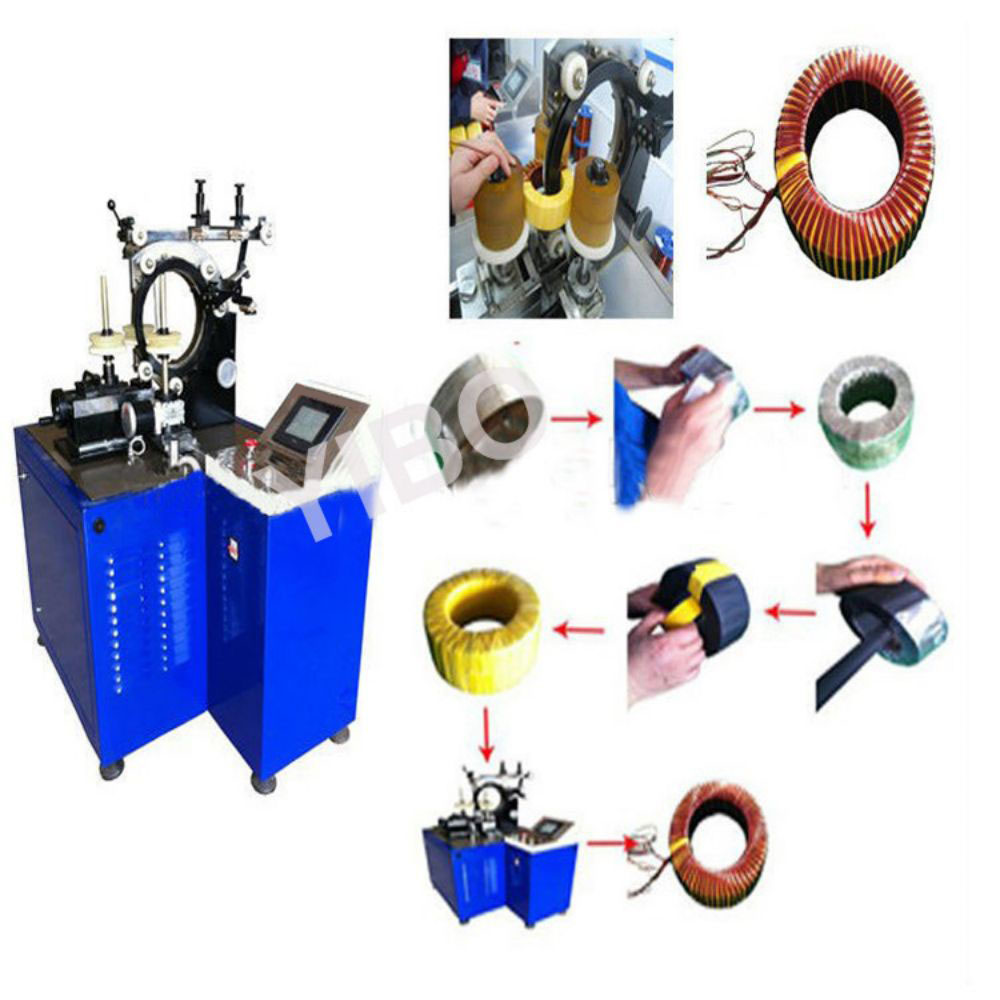

Imashini zikoresha amashanyarazi menshi

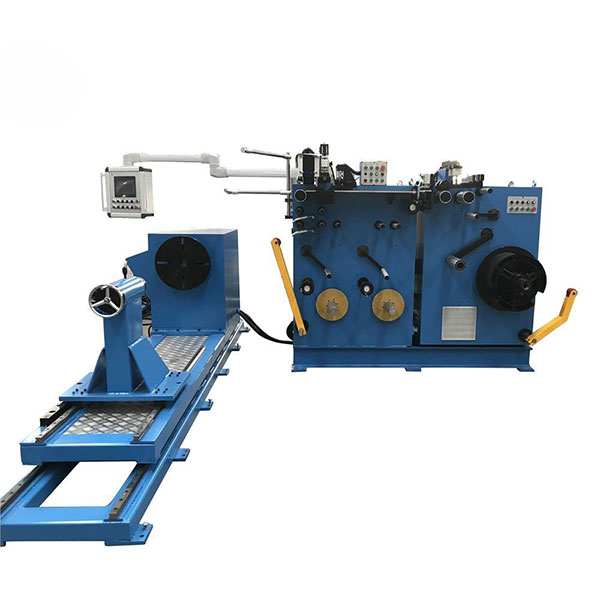

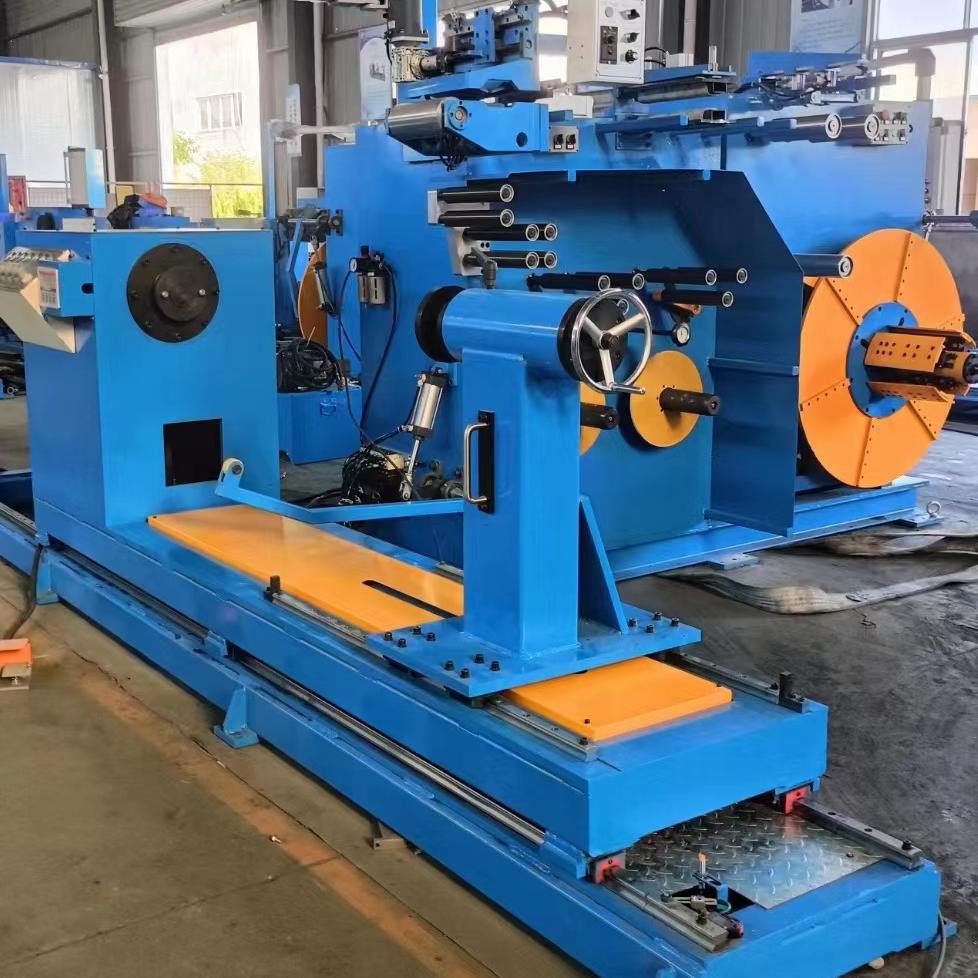

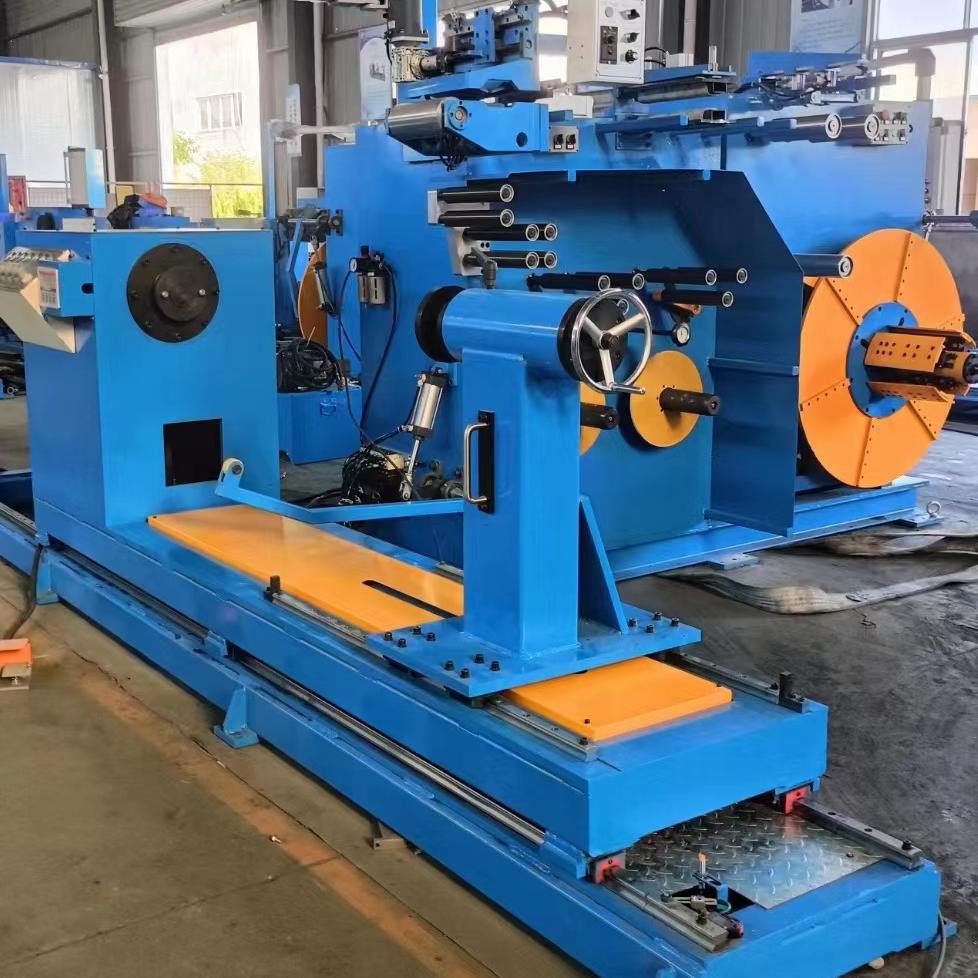

Ubusobanuro bunoze no gukora neza mugukora coil Imashini nini ya voltage foil imashini ihinduranya ibikoresho nibikoresho byabugenewe byabugenewe kugirango bihuze ibikenerwa n’umusemburo mwinshi wa voltage. Igizwe nibice byinshi byingenzi bikorana kugirango tumenye neza neza kandi neza neza.

Aluminium foil uncoiler

Undinders ishyigikira kudashaka, gukusanya no gusohora imirongo ya aluminium. Ifite uruziga ruzengurutse rufite imiyoboro ine ifata ibice bine byaguka, bituma ingoma ishyigikirwa ku ngoma yipakurura hifashishijwe hydraulic. Moteri ifite imbaraga nyinshi za servo itwara spindle kugirango idapfundura neza, gupakurura, no gusubiza inyuma, bikwemerera guhindura imikorere yakazi vuba kandi byoroshye. Igishushanyo cyemeza ko gutandukana kwa tension bihoraho murwego ntarengwa mugihe cyo guhinduranya. Ibice bibiri byibikoresho byigenga byigenga byinjijwe mumashini idashaka, irashobora gutanga intera nini yo guhinduranya impagarara.

Igikoresho cyo kumanura gifata pneumatike kugirango gitange imikorere ihoraho ya moteri ya servo, yoroshye, isukuye kandi ifite umutekano kugenzura. Umutako wose uhujwe na fuselage unyuze kumurongo munini uyobora umurongo kandi ufite sisitemu yo gukosora servo. Amabwiriza ya sisitemu yo kugenzura PLC kandi ashingiye kubitekerezo byerekana ibimenyetso byerekana gutandukana, imashini idashaka igenda neza neza kuri gari ya moshi iyobora kugirango ihindure umwanya wa fayili kugirango hamenyekane neza aho ikosorwa rihagaze.

Sisitemu yo guhinduranya

Imashini izunguruka iherereye kumpera yimbere yibikoresho kandi izengurutsa kaseti ya fayili izengurutse uruziga. Shyira imbere imbaraga za mashini nibisohoka mumashanyarazi mugushushanya imashini ihinduranya, urebye ingano ntarengwa yibikoresho byakazi hamwe nimbaraga zo kwaguka zisabwa nibikorwa. Igikonoshwa cyo hanze cyimashini izunguruka isudira hamwe nibyuma byibyuma hanyuma bigatunganywa nyuma yo kuvura no kugabanya ibibazo.

Sisitemu ya gare yo kohereza hamwe na garebox igizwe na moderi nini-module ya helical, imyirondoro yinyo yayo ikomanta ikoresheje tekinoroji yo gusya. Ibi bitanga imbaraga zubukanishi hejuru yumuriro mwinshi, bigatuma imikorere ikora neza hamwe nurusaku ruke rwibikoresho byose.

Imashini ifata umuvuduko ukabije wihuta kugirango itange umuvuduko mwinshi hamwe n umuvuduko ukwiye wihuta. Itanga umuriro uhagije n'umuvuduko ntarengwa kugirango uhuze ibisabwa muburyo butandukanye. Mugihe cya spindle guhinduranya, gutangira no guhagarika ahantu hihuta byashyizweho neza, kandi bifite imikorere ya feri kugirango bitezimbere ibikorwa. Ifata moteri ifite ingufu nyinshi kandi ifite imbaraga nyinshi.

Sisitemu yo kugenda ibumoso / iburyo: Ibumoso / iburyo bwimashini ihinduranya bigerwaho hifashishijwe sisitemu ya moteri ya servo no kugabanya umubumbe wuzuye.

Sisitemu iremeza gutandukana kwinshi mubice bibiri bya coil mugihe cyo kuzunguruka no kugenda.

Imyitozo ngororamubiri irashobora gutegurwa hakoreshejwe ecran ya ecran hanyuma igakorwa ukoresheje buto kugirango ikore byoroshye.

Sisitemu yo guhinduranya

Igikoresho cya insulasiyo: Igikoresho cyiziritse ntigishobora gushyigikira guhinduranya ibikoresho kandi bikaguka mugihe cyizuba. Imashini ihinduranya ifite ibikoresho bibiri byokwirinda bidashobora gukoreshwa, bishobora gutanga ibice bibiri byimpapuro zokwirinda cyangwa firime yubushyuhe icyarimwe. Uburyo bugizwe nibice bine: uruziga rucanwa, sisitemu yo gutwara, uruzitiro rwabigenewe, hamwe nigikoresho cyo kumena. Mugukanda kuri valve yumuyaga kumpera yingoma yaka, blok yo kwagura reberi isubira inyuma, bigatuma ibikoresho byinjizwa muburyo bwingoma. Koresha imbunda yo mu kirere kugirango urekure reberi yo kwagura unyuze mu kirere kugira ngo ukosore kandi ushyire hejuru ya coil kandi ukomeze kwaguka bikenewe mu gihe cyo kuzunguruka. Impagarara zirashobora guhindurwa muburyo bworoshye kandi uko bishakiye binyuze mumurongo ngenderwaho hamwe no kuzimya. Sisitemu yimbaraga za insulasiyo idashaka gufata moteri ya servo itomoye kandi ifite intera nini yo guhinduranya. Imbaraga z'igikoresho cyo kumanura zigenzurwa na induction pneumatic, yohereza amabwiriza kuri moteri ya servo kugirango imenye imikorere ihoraho. Igishushanyo cyerekana kugenzura byoroshye, gukora isuku, umutekano no guhinduranya kugirango byoroherezwe.

Igikoresho

Iki gikoresho cyo gukuramo gikuraho neza burr kuri kasete ya fayili mugucunga umuvuduko wumwuka ukoreshwa mubice bibiri byerekana neza. Iyi nzira ntabwo ikuraho burrs gusa, ahubwo inatanga icyerekezo kinini cyo kunyeganyega kumurongo ufite ibizunguruka neza. Ibi birashobora guhindurwa ukurikije ubunini, ubugari nubushake bwa kaseti, bikagabanya neza burrs kumpera ya kaseti ya aluminium. Umuvuduko wumwuka urashobora kandi guhindurwa muburyo butandukanye ukurikije ubunini bwa file, cyane cyane kubikoresho byimbitse, bikagabanya cyane ibyago byimyanda yibikoresho mugihe cyo kuzunguruka.

Gutanga ni inzira ikomeye idashobora kwirengagizwa, kubera ko burr itavuwe cyangwa idahumanye irashobora gutobora impapuro zikingira, bigatera imiyoboro migufi cyangwa umuriro. Ibigo byinshi byibanze ku kamaro kiyi ngingo.

Icyitonderwa

Igishushanyo cyihariye - igikoresho cyo kwanduza cyahujwe na uncoiler kandi kirashobora kugenda gitambitse kugirango kigabanye guhindura no guhangana mugihe cyo kwishyura icyuma cyatandukanijwe. Ibi byemeza neza neza ibicuruzwa, bikuraho neza umwanda hejuru yumuti wa aluminium, kandi bikazamura ireme ryibicuruzwa.

Igikoresho cyo gusudira cyikora: Iki gikoresho cyo gusudira cyujuje ibyangombwa byo gusudira byimigozi ya fayili kandi ikayobora.

Kugira ngo ushobore gusudira lap, urwasaya rw'ibikoresho byo gusudira rushobora kuzunguruka ku rugero runaka.

Urwasaya rwo hepfo rushobora gukoresha umuvuduko wo hejuru kandi urwasaya rushobora gusimburwa nkuko bikenewe. Clamp ya sisitemu yo gusudira yashyizwe kuri fuselage, kandi imbunda yo gusudira, sisitemu yo kugenda byikora, na clamp irashobora kugenda ibumoso niburyo kuri clamp. Nyamara, iyo gahunda yo gusudira imaze kurangira, uburyo bwo gusudira busubira inyuma ibumoso, burekura umwanya uhindagurika kugirango byoroshye gukora.

Imbunda yo gusudira yashyizwe kuri trolley igendanwa kandi irashobora guhindurwa ahantu hatandukanye kugirango ihuze nuburyo butandukanye bwo gusudira. Trolley igendanwa itwarwa na moteri yihuta ihinduka, kugabanya na screw. Umuvuduko wo gusudira urashobora guhinduka byoroshye. Ubu buryo bwo gusudira bukoresha uburyo bwo guhinduranya hamwe nubu buryo butaziguye kuri argon arc gusudira (TIG) udakeneye ibikoresho byuzuza.

Sisitemu yo kugenzura ibikoresho bya elegitoronike: Sisitemu yo kugenzura ibikoresho bya elegitoronike itanga amabwiriza kubintu bitandukanye byakozwe, nko guhinduranya, guhinduranya gutandukana, kubara lap no kwerekana ibintu bitandukanye, bishingiye ku mibare ya sisitemu yo kugenzura PLC ukoresheje porogaramu zacu bwite hamwe nuburyo bukoreshwa. Ishyirwa mu bikorwa rya sisitemu zitandukanye ryizewe. Abakoresha bakeneye gusa kwinjiza ibipimo byakazi binyuze murwego runini rwo gukoraho HMI kugirango barangize byoroshye umusaruro mwinshi wibikorwa hamwe nibisobanuro bimwe.

Ibikoresho byose birashobora kandi gukoreshwa nintoki binyuze muri buto yo kugenzura, harimo gukora ako kanya no guhuza ibikorwa. Hano hari buto nyinshi zihutirwa kumwanya munini wo kugenzura nibikoresho byingenzi. Iyo ibintu bidasanzwe bibaye, sisitemu irashobora gufungwa mugihe kugirango umutekano ubeho.

Ibikorwa byose bya sisitemu birashobora gukorwa binyuze muri konsole rusange. Sisitemu ya pneumatike: Sisitemu ikoresha uburyo bwo kugenzura no gucecekesha ibintu byinshi kugira ngo urusaku rw’imashini yose ruri munsi y’ibikoresho byatumijwe mu mahanga. Umuvuduko nigipimo cya buri shami birashobora guhinduka byigenga. Irangizwa rya buri gikorwa cya pneumatike kigenzurwa na gahunda ya PLC.

Murugo

Murugo