01

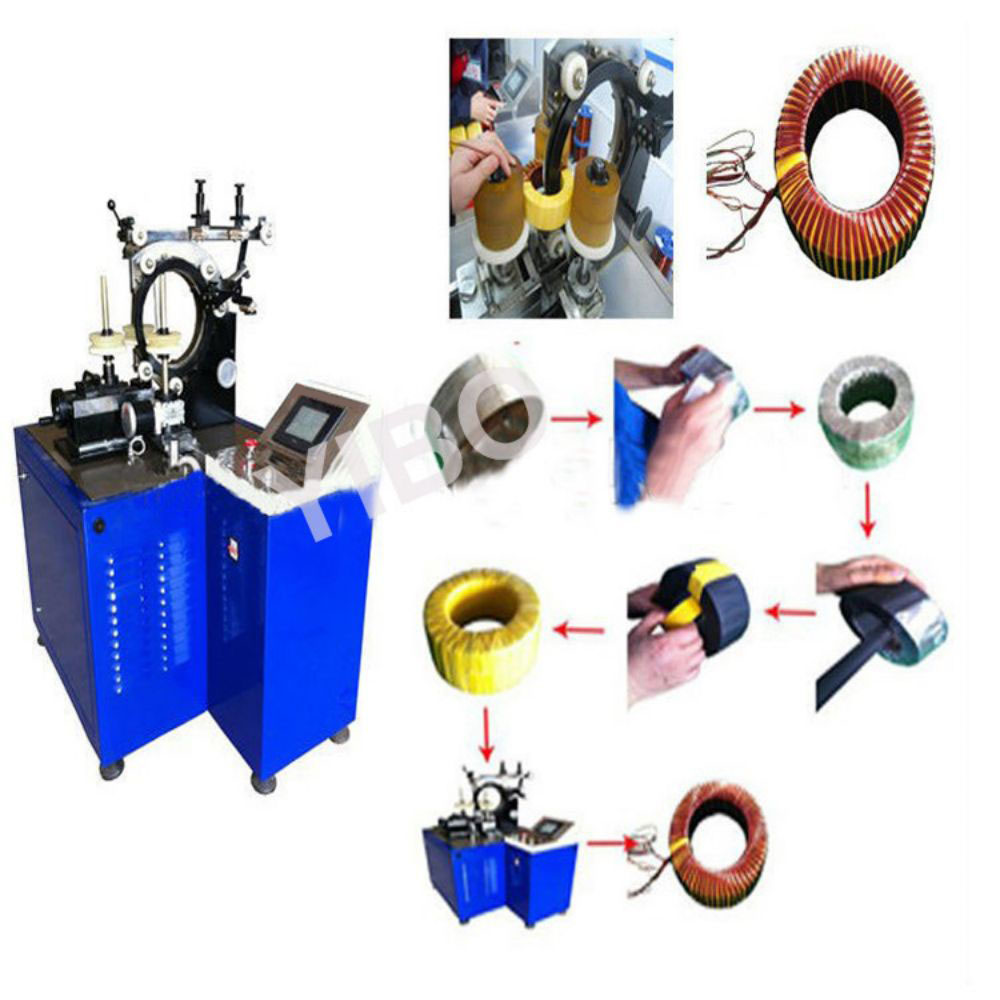

Amorphous Triangular Three-Dimensional High And Low Voltage Automatic Machine

Makina athu opanga ma amorphous high and low voltage Integrated automatic winding makina apangidwa kuti asinthe kamangidwe ka ma amorphous atatu-dimensional transformer cores. Chida ichi cham'mphepete chinapangidwa kuti chizitha kuyendetsa bwino komanso kuwongolera bwino kwa ma windings otsika voteji komanso ma windings apamwamba.

Ndi kapangidwe kake katsopano, kapangidwe kake, kuphatikiza kwakukulu ndi ntchito ziwiri, imachepetsa kwambiri nthawi yokhotakhota pomwe ikupereka mwayi kwa ogwiritsa ntchito ndikuchepetsa ntchito yawo. Zotsatira zake, ma windings apamwamba ndi otsika amawonetsa kusasinthasintha kwabwino.

Kuchuluka kwa ntchito

Kampani yathu ya amorphous high and low voltage in Integrated automatic winding machines ndi zida zomangirira zokha zogwira ntchito zambiri zomwe zimagwiritsidwa ntchito makamaka kupiringa mapindikidwe a ma amorphous atatu-dimensional transformer cores.

Oyenera kupanga ma windings otsika-voltage ndi ma windings apamwamba a 50KVA-630KVA amorphous (silicon steel) atatu-dimensional transformer cores.

Ndiosavuta kusonkhanitsa ndipo imatha kupanganso ma windings apamwamba komanso otsika kwambiri. Imakwaniritsa kusanja koyenera komanso koyenera, ndikupangitsa kuti ikhale yankho lazonse.

Zatsopano zaukadaulo za amorphous maginito cores

Pogwiritsa ntchito ma amorphous alloys, omwe amadziwika ndi maginito abwino kwambiri, monga zida zoyambira zopangira ma thiransifoma, kutayika kotsika kwambiri kumatha kuchitika. Komabe, ma amorphous alloys ali ndi zinthu zapadera zomwe ziyenera kuganiziridwa mosamala pakupanga ndi kupanga, kuyang'ana kwambiri pakukhudzidwa kwawo ndi kupsinjika kwamakina. Poyerekeza ndi mafunde achitsulo a silicon pachimake, izi zimafuna zotsogola zatsopano pazida zazikulu.

Non-contact core winding teknoloji

Mapangidwe apangidwe amayenera kupewa njira zopangira zitsulo zomwe zimagwiritsidwa ntchito ngati gawo lalikulu lonyamula katundu. Pamayendedwe amtundu wamagetsi otsika kwambiri, njanji ya slide giya yomangika imakhazikika pachimake chachitsulo kudzera pa ma bolts, kupangitsa kupsinjika konse kwamakina pamapangidwe achitsulo pakatikati pachitsulo. Chifukwa cha zinthu zawo zakuthupi, ma amorphous cores amakhudzidwa kwambiri ndi kupsinjika kwakunja ndipo amatha kukhudzidwa kwambiri ndi kugwedezeka panthawi yokhotakhota.

Izi zingayambitse kutayika kwakukulu komanso ngakhale chiopsezo chowonjezereka cha maulendo afupikitsa.

Makina athu atsopano amabweretsa makina omwe amayimitsa nkhungu yamagetsi pachimake chachitsulo, kulola kuti koyilo yokhotakhota kuzungulira pachimake chachitsulo popanda kukhudza. Izi zimatsimikizira kuti njira yokhotakhota ilibe kanthu pakuchita kwenikweni. ii) Mphamvu yamagetsi yophatikizika kwambiri komanso yotsika

Dual-function Technology

Njira yokhotakhota yachikhalidwe imafuna makina awiri osiyana omwe ali ndi ntchito zosiyanasiyana. Chitsulo chachitsulo chiyenera kutsekedwa ndi kuikidwa pamakina opangira zojambulazo, ndiyeno chotsirizidwacho chimasamutsidwa ku makina opangira magetsi othamanga kwambiri kuti azitha kupukuta ndi kupukuta kwamagetsi apamwamba kwambiri.

Izi zimafuna njira zingapo zamanja ndikuyenda mobwerezabwereza, zomwe zimapangitsa kuti ntchitoyo iwononge nthawi komanso yogwira ntchito. Komanso, zimakhudza ntchito pachimake.

Zotsatira za kafukufuku ndi chitukuko cha kampani yathu ndizophatikizika kwambiri ndi zida zogwirira ntchito zapamwamba komanso zotsika. Pogwiritsa ntchito makinawa, mapindikidwe amagetsi otsika amatsata mafunde amphamvu kwambiri, ndikumaliza mafunde atatu okwera ndi otsika a thiransifoma imodzi. Ndi kukakamiza kumodzi kokha, makinawo amatha kugwira ntchito zokhotakhota zotsika-voltage komanso mafunde okwera kwambiri, kuchotsa masitepe osafunikira ndikuwonjezera magwiridwe antchito. iii)

Tekinoloje yowongoka yokha (kuphatikiza waya wozungulira)

Popeza mawonekedwe a ma coil amitundu itatu apakati amafunikira kuvulazidwa ndi pachimake, makina apamwamba kwambiri ndiofunikira kuti awonetsetse kuti ntchito ikuwonjezeka.

Zipangizo zathu Zimaphatikiza ma seti opitilira 20 a makina apamwamba kwambiri a digito ndi masensa anzeru ambiri kuti akwaniritse kuwongolera kolondola kwamayendedwe apakatikati, kayendedwe ka foil / mizere, kuyang'anira, ndi ntchito zakutali za digito ndi kukonza.

Zinthu zazikuluzikulu zikuphatikiza kukhazikika kwapakati kwa 120 °, core lateral / longitudinal position tracking algorithm, ma waya odziyimira pawokha, waya wozungulira wozungulira, waya wothamanga kwambiri wa servo wokhazikika wa torque, ndi foil frame hydraulic self-lock for control tension control.

Makina omangirira okwera komanso otsika kwambiri amawongolera kusasinthika kwazinthu komanso kupanga bwino, ndipo amapereka HMI yolemera (mawonekedwe a makina amunthu) ndi kuthekera kwa mawonekedwe a data kuti azindikire magwiridwe antchito akutali ndikukonza zida, zomwe zimathandizira kusintha magwiridwe antchito a fakitale ya digito.

Ndilo kusankha koyamba kwa amorphous atatu-dimensional transformer winding devices. iv)

Kuwunika ndi ukadaulo wapa digito wogwiritsa ntchito ndi kukonza

Zipangizo zathu zili ndi kuyang'anira ndi kuyang'anira ntchito zakutali za digito ndi luso lokonzekera, kuphatikizapo makina owonetsera mavidiyo a masiteshoni anayi, kuyankhulana kwakutali ndi ntchito zolamulira, ndi MES (Manufacturing Execution System) zolumikizira digito.

Zomwe zasonkhanitsidwa zitha kupezeka nthawi yomweyo kuti ziwunikire momwe zinthu zikupangidwira komanso zidziwitso za alamu ya zida, monga kuwona momwe mzere wopangira mzere ugwirira ntchito ndikupereka zambiri munthawi yeniyeni kuwonetsetsa kuwunika momwe zida zimapangidwira.

Kuphatikiza apo, oyang'anira fakitale amatha kupeza zidziwitso zopanga patali kudzera m'magawo apakompyuta kuti awonetsetse kuyang'anira bwino ndikuwongolera magwiridwe antchito munthawi yeniyeni ya zida. Kuphatikiza pa kujambula zidziwitso zopanga, zolakwika za zida zitha kuyang'aniridwanso kudzera pa intaneti ya zida.

Mukalumikizidwa ndi intaneti, data yokhazikika ya chipangizocho imatha kuyang'aniridwa pogwiritsa ntchito ukadaulo wa IoT (Internet of Things). Zambiri zomwe zimadutsa mulingo woyenera zimabweretsa chenjezo loyambirira, ndipo mamanenjala amalandila zidziwitso pama terminals apakompyuta, potero amapewa kutayika kwa kupanga komwe kumachitika chifukwa chakulephera kosayembekezereka.

Kunyumba

Kunyumba