01

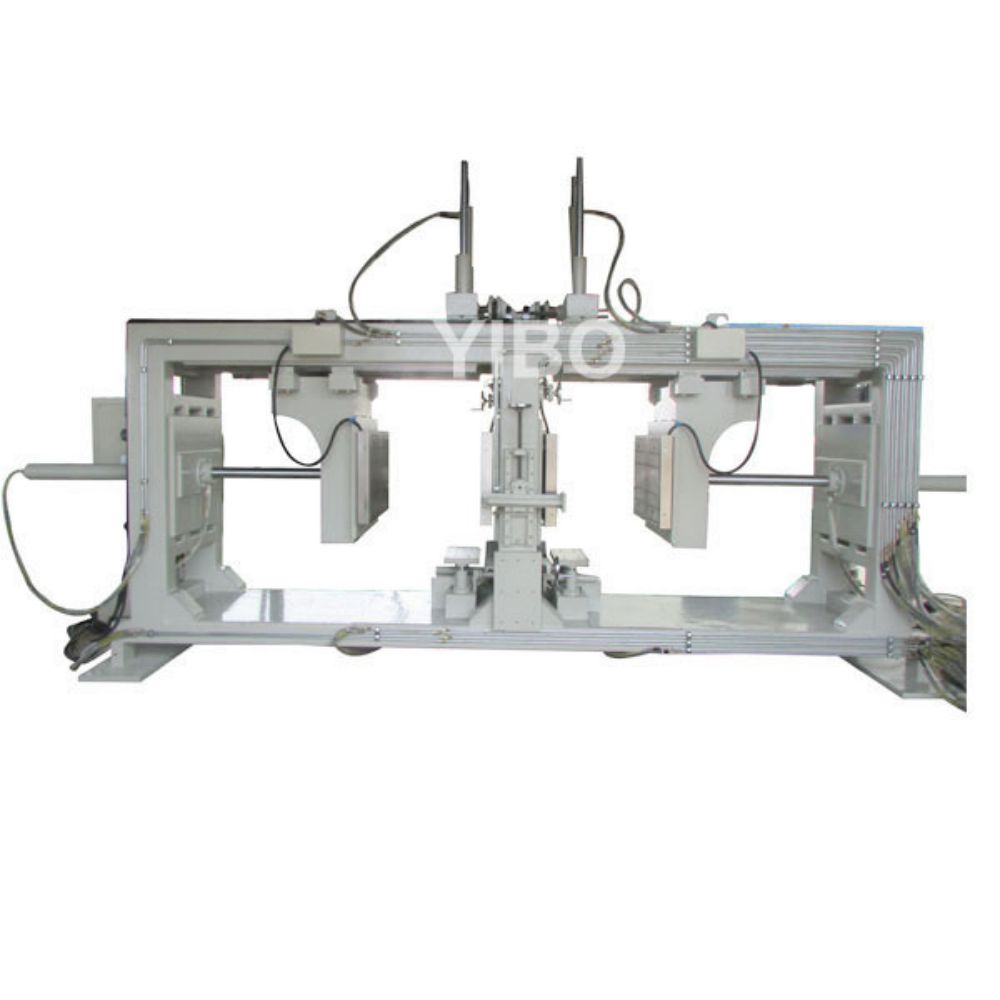

Double Station APG Clamping Machine

Bagian rangka mesin

Mekanisme pigura integral: perawatan anil sawise welding kanggo ngilangi stres internal

45 model guide linear, support lan guide obah Cithakan

Hanging obah piring

Tekanan klem utama 200KN

Silinder tutup utama: Diameter piston 125mm

Jarak maksimum antarane rong piring pemanasan yaiku 1750mm lan jarak minimal yaiku 200mm

Parameter clamping horizontal kiwa lan tengen

1.1 Stasiun A,B bekisting horisontal 900*600mm (Length×Width),

1. pasukan clamping horisontal maksimum 250KN

1.3 Jarak nutup minimal yaiku 240mm lan jarak bukaan maksimal yaiku 1600mm

1.4 Cithakan sing bisa dipindhah bisa nggawa cetakan kanthi bobot maksimal 5 ton

1.5 Kacepetan gerakan nutup paling cepet 3.2m / min lan paling alon 1.8m / min

1.6 Daya pemanasan yaiku 48KW 380V

1.7 Pemanasan suhu maksimum 300 ℃

Ngiwa lan tengen paramèter inti-narik

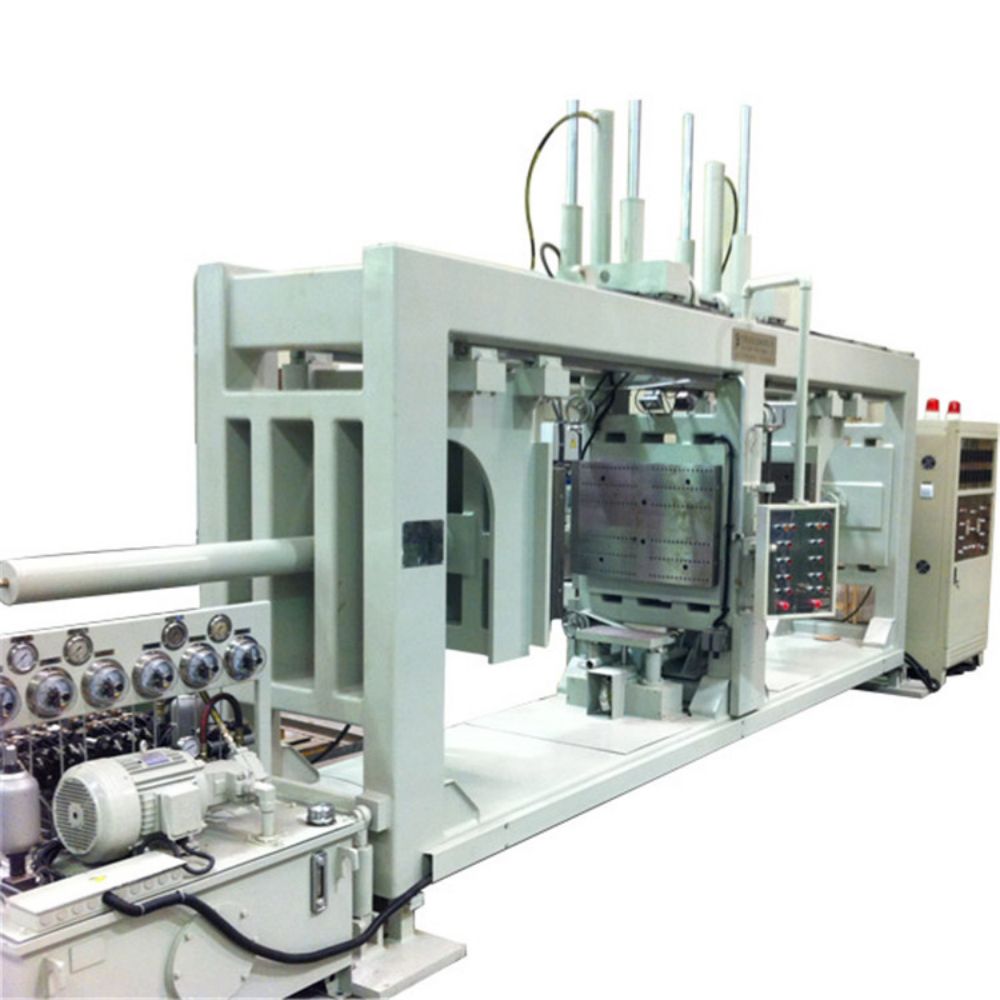

2.1 Cithakan tarik inti ndhuwur 640×240mmx40mm (Dawa×Jembar)

2.2 Stroke maksimum 760mm

2.3 pasukan clamping maksimum 7 ton

2.4 Kacepetan tutup sing paling cepet yaiku 3.2m / min

2.5 Cithakan obah bisa nggawa cetakan kanthi bobot maksimal 1 ton

2.6 Daya pemanasan sing dilindhungi kanggo cetakan yaiku 4KW 220V

2.7 Pemanasan suhu maksimal 250 ℃ kanggo narik inti

~ ndhuwur inti-narik piring obah; z

Silinder inti ndhuwur: stroke 800MM, diameter piston 80MM, stroke 400MM;

2.1 Cithakan tarik inti ndhuwur 650×260mmx45mm (Dawa×Jembar)

2.2 Stroke maksimum 900mm

2.3 Gaya clamping maksimum 10 ton

2.4 Kacepetan tutup sing paling cepet yaiku 3.2m / min

2.5 Cithakan obah bisa nggawa cetakan kanthi bobot maksimal 4 ton

2.6 Daya pemanasan sing dilindhungi kanggo cetakan yaiku 6KW 220V

~ Silinder inti ngisor: stroke 800MM, ora ana pit penggalian, diameter piston 80MM, stroke

400 MM;

~ Jarak antarane piring drawing inti lan tengah peralatan punika: minimal 270MM, maksimum 1020MM;

~ Silinder terjemahan: stroke 550MM;

~ Guide sleeve lan guide post: 2 sets, diameteripun 50MM;

~ A inti narik plate 550 * 240MM, digunakake kanggo nginstal inti narik piranti ing jamur;

~ 1 set silinder penarik inti ngisor lan silinder pindah lan piranti proteksi ril panuntun supaya ora ngrusak bahan karet ing bagean obah sing gegandhengan

Potongan;

~ Aksesoris sing gegandhengan: soket listrik, pipa minyak, lsp.

Munggah lan mudhun inti narik

~ inti ngisor narik piring obah;

Silinder penarik inti ngisor: stroke 800MM, pit penggalian, diameter piston 70MM, (stroke 400MM; Aja nggali bolongan)

~ Jarak antarane papan narik inti lan tengah piranti yaiku 270MM (minimal) lan 1020MM (maksimum).

~ munggah lan mudhun inti narik terjemahan: stroke 500MM; (listrik, sekrup kunci)

Guide sleeve lan guide post: 2 sets, diameteripun 65MM;

~ piring narik inti 550 * 240MM, digunakake kanggo nginstal piranti narik inti ing cetakan;

1 pesawat saka ngisor inti-narik silinder lan lenga obah silinder lan guide alur pangayoman piranti kanggo ngindhari karusakan saka bagean obah cocog dening lim;

~ Aksesoris sing gegandhengan: soket listrik, pipa, lsp.

PLC + kontrol layar tutul

Antarmuka operasi prasaja lan cetha, lan operasi kutipan bisa ditampilake.

~ Fungsi piranti, mode operasi: manual, otomatis, operasi siji langkah.

Hak operasi: Nulis lan nelpon program proses produk mbutuhake sandhi kanggo mlebu, kanggo nyegah program kasebut diowahi lan ditelpon kanthi kekarepan utawa bocor.

~ Nganggo kacepetan segmented: kacepetan nutup kontrol ing orane tumrap sekolah kanggo mesthekake efficiency produksi lan nglindhungi jamur ing wektu sing padha (dipérang dadi cepet lan alon kacepetan lan luwes, owah-owahan kacepetan otomatis nalika nyedhak jamur). Die meksa ngawasi relief meksa: bisa kanthi otomatis ngawasi meksa nyata-wektu silinder hydraulic, nalika meksa ngluwihi Nilai nyetel, relief meksa otomatis.

Ngarep

Ngarep