Wannan yana kawar da sauye-sauyen hatimi a lokacin iska. Bugu da kari, na'urar kuma tana da na'urar firikwensin gyara. Yana amfani da na'urori masu auna firikwensin hoto mara lamba don gano duk wani sabani a gefen foil kuma yana gyara shi da ƙarfi ta hanyar injin gyara karkatar da mai amfani. Tsarin yana da babban madaidaici, babban amsawa, da babban abin dogaro, kuma daidaiton gyaran yana cikin +/- 0.4mm. An raunata ƙullun bangon ƙarfe da foils na aluminum masu kauri daban-daban a matsayin masu gudanarwa, kayan rufewa masu faɗi azaman insulation, da kunkuntar kayan rufewa azaman rufin ƙarewa. Ana yin coils ta hanyar juzu'i guda ɗaya akan na'ura mai jujjuyawar foil mai ƙarfi.

Na'urar kuma tana kammala walda na ciki da na waje na nada, da kuma jujjuyawar saman saman. Tare da cikakkiyar aikin sa, injin yana ba da tallafi mai yawa don kera juzu'i na foil zuwa ƙayyadaddun da ake buƙata. Ya zama kayan aiki masu mahimmanci don samar da sassan irin waɗannan kayan lantarki. Zuba hannun jari a cikin na'ura mai jujjuyawar foil mai ƙarfi yana tabbatar da ingantaccen tsarin samarwa, ƙirar ƙira mai inganci da haɓaka gabaɗayan ayyukan samar da taswira.

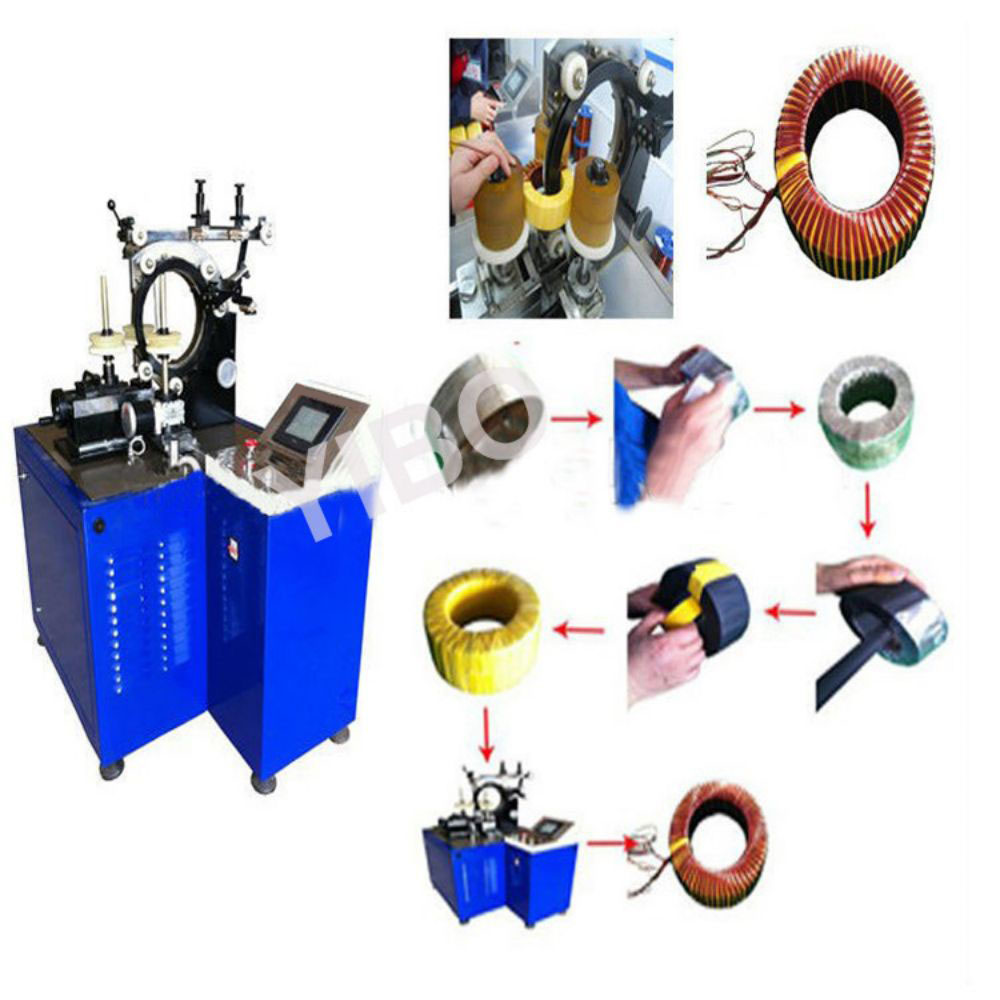

Injin jujjuyawar foil mai ƙarfi

daidaito da inganci a cikin masana'antar na'ura mai ɗaukar nauyi mai jujjuyawar iska shine ingantaccen kayan aiki wanda aka kera musamman don biyan buƙatun samar da wutar lantarki mai ƙarfi. Ya ƙunshi maɓalli da yawa waɗanda ke aiki tare don tabbatar da ingantacciyar iska da ingantaccen ingancin coil.

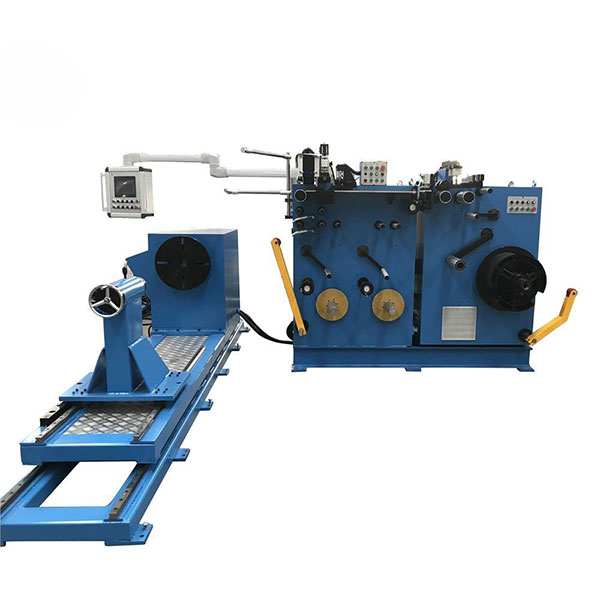

Aluminum foil uncoiler

Unwinder yana goyan bayan kwancewa, tarawa da fitar da filayen foil na aluminum. Yana da madaurin zagaye tare da hanyoyin haɗin kai huɗu waɗanda ke riƙe da tubalan da za a iya faɗaɗawa huɗu, suna ba da damar goyan ganga a kan ganga mai ɗaukar nauyi ta hanyar goyan bayan na'urar ruwa. Motar servo mai ƙarfi tana sarrafa sandar don kwancewa daidai, saukewa, da kuma baya, yana ba ku damar daidaita yanayin aiki cikin sauri da sauƙi. Wannan ƙira yana tabbatar da cewa karkatar da tashin hankali yana dawwama a cikin mafi ƙarancin kewayon yayin aikin iska. An haɗa nau'i biyu na na'urorin damfara masu zaman kansu a cikin injin kwance, wanda zai iya ba da ɗimbin daidaitawar tashin hankali.

Na'urar damping tana ɗaukar iko na pneumatic don samar da aikin tashin hankali akai-akai don motar servo, wanda ya dace, mai tsabta da aminci don sarrafawa. An haɗa duka kayan aikin decoiler zuwa fuselage ta hanyar manyan ginshiƙan jagorar linzamin kwamfuta kuma an sanye shi da tsarin gyaran servo. A ƙarƙashin umarnin tsarin kula da PLC kuma bisa ga amsawar siginar gano ɓarna, injin kwance yana motsawa daidai tare da layin jagora don daidaita matsayi na foil don tabbatar da daidaitaccen matsayi da gyare-gyare na ɓarna.

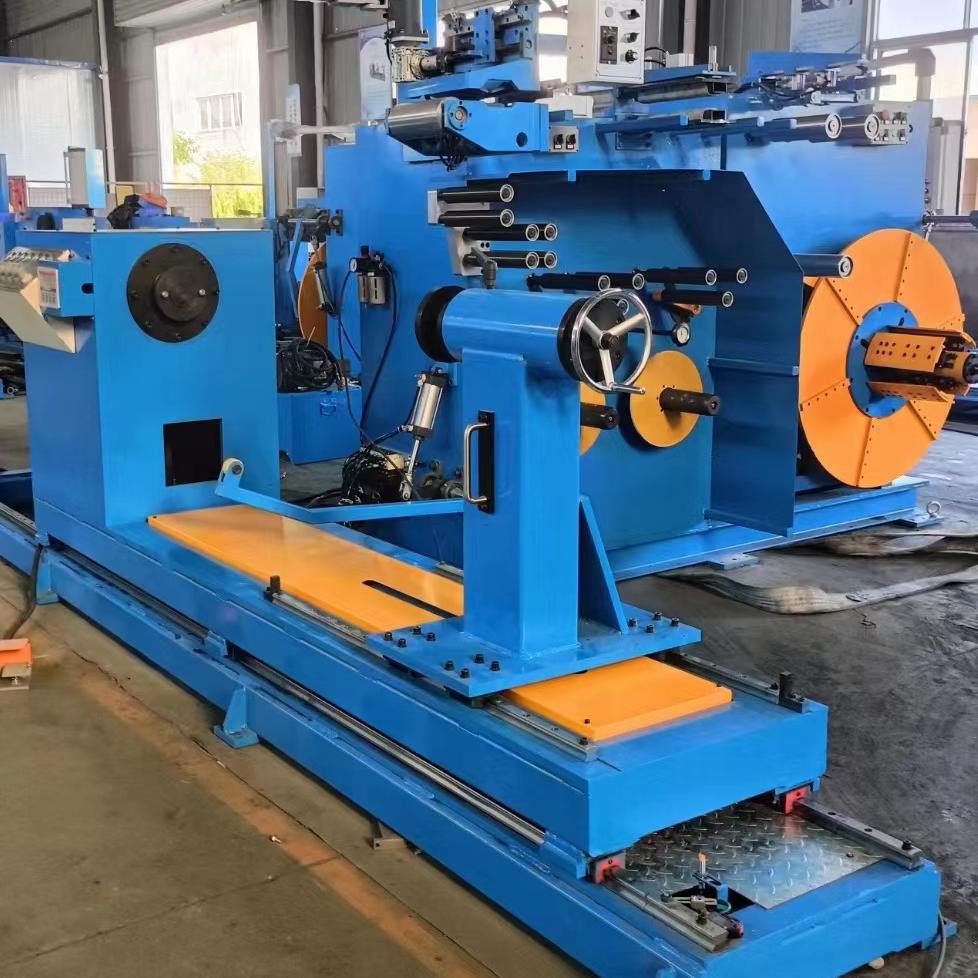

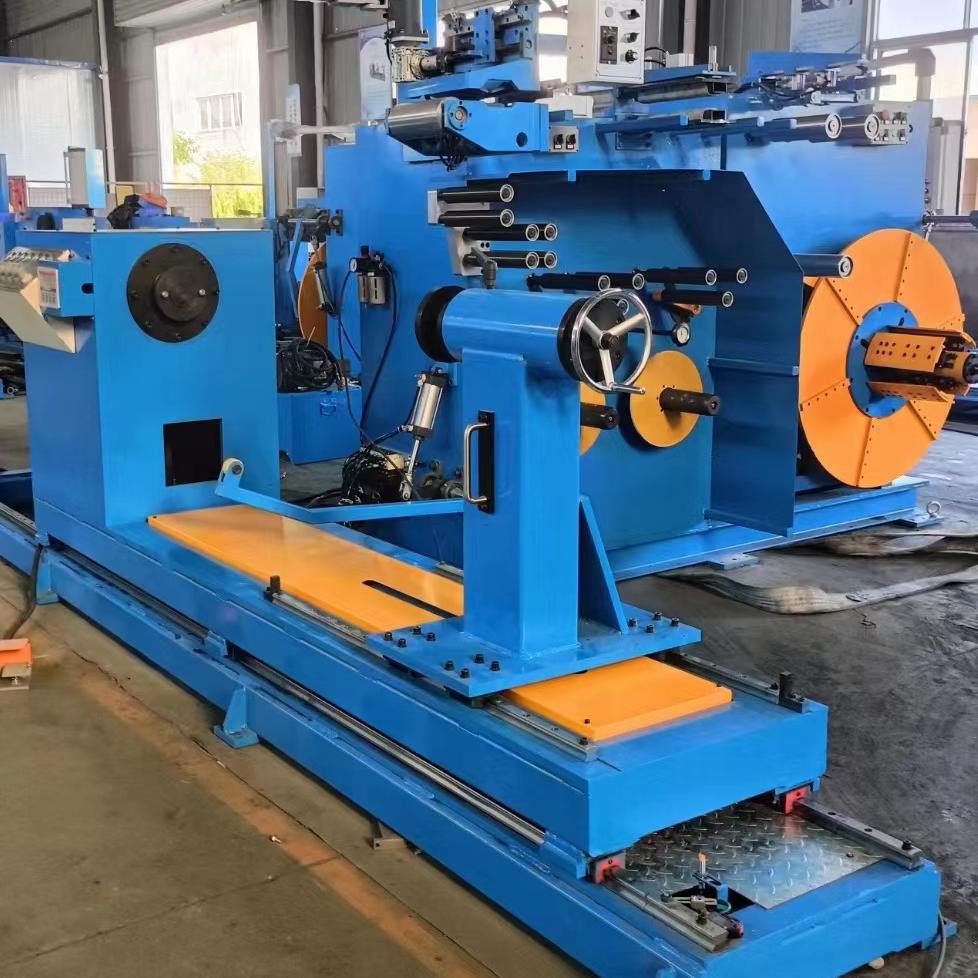

Tsarin iska

Na'ura mai jujjuya tana samuwa a gaban ƙarshen kayan aiki kuma yana nannade tef ɗin tsare a kusa da shingen iska. Ba da fifikon ƙarfin injina da ƙarfin fitarwa a cikin ƙirar injin iska, la'akari da matsakaicin girman kayan aikin da ƙarfin faɗaɗa da ake buƙata ta hanyar. A waje harsashi na winding inji ana welded da kauri karfe faranti da kuma sarrafa bayan annealing da danniya jiyya.

Tsarin gear na watsawa da akwatin gear ya ƙunshi manyan gears helical-module, bayanan haƙoran da aka taurare ta amfani da fasahar niƙa. Wannan yana tabbatar da ƙarfin injina a babban fitarwa mai ƙarfi, yana tabbatar da aiki mai santsi da ƙananan amo na duk kayan aiki.

Injin yana ɗaukar ƙa'idodin saurin mitar mai canzawa don samar da matsakaicin juzu'i da saurin juyi da ya dace a ƙaramin gudu. Yana ba da isasshen karfin juyi da matsakaicin gudu don saduwa da buƙatun hanyoyin iska daban-daban. Yayin aikin jujjuyawar sandal, an saita gangaren hanzari da farawa yadda ya kamata, kuma yana da aikin birki don inganta samuwar aiki. Yana ɗaukar injin tuƙi mai ƙarfi kuma yana da dumbin wutar lantarki.

Tsarin motsi na hagu / dama: Motsi na hagu / dama na injin iska yana samuwa ta hanyar tsarin motar servo da madaidaicin mai rage duniya.

Wannan tsarin yana tabbatar da mafi girman karkatawar saiti biyu na coils yayin iska da motsi.

Za'a iya saita ƙarfin motsa jiki ta hanyar allon taɓawa kuma kunna ta maɓalli don sauƙin aiki.

Tsarin iska

Na'urar da ke rufewa: Na'urar da za ta cire kayan rufewa tana goyan bayan jujjuyawar abin rufewa kuma yana tabbatar da faɗaɗa shi yayin aikin iska. Na'ura mai jujjuya tana sanye take da nau'ikan nau'ikan ɓoyayyen ɓoyayyiyar ɓarna, wanda zai iya samar da nau'i biyu na takarda mai rufewa ko fim ɗin zafi a lokaci guda. Na'urar ta ƙunshi sassa huɗu: na'ura mai ɗaukar nauyi mai ƙarfi, tsarin tuki, abin nadi mai jagorar insulation, da na'urar damfara. Ta hanyar latsa bawul ɗin iska a ƙarshen drum ɗin da za a iya zazzagewa, shingen fadada roba ya koma baya, yana ba da damar shigar da kayan kai tsaye a cikin ganga. Yi amfani da bindigar iska don sakin shingen faɗaɗa roba ta hanyar bawul ɗin iska don gyarawa da hura wutar da aka keɓe da kiyaye yanayin faɗaɗa da ake buƙata yayin aikin iska. Za'a iya daidaita tashin hankali cikin dacewa da sabani ta hanyar abin nadi na jagora da abin nadi mai damping. Tsarin wutar lantarki na na'urar cirewa mai rufewa yana ɗaukar ingantacciyar injin servo kuma yana da kewayon daidaita yanayin tashin hankali. Ana sarrafa ikon na'urar damping ta hanyar shigar da pneumatic, wanda ke aika umarni zuwa motar servo don gane aikin tashin hankali akai-akai. Wannan zane yana tabbatar da sauƙin sarrafawa, tsaftacewa, aminci da jujjuyawar jujjuyawa don ƙarin dacewa.

Na'urar cirewa

Wannan na'urar da ke cirewa da kyau tana cire burs daga kaset ɗin foil ta hanyar sarrafa matsin iska da aka yi akan sahu biyu na madaidaicin rollers. Wannan tsari ba wai kawai yana kawar da burbushi lafiya ba, har ma yana ba da motsin motsi mai jujjuyawa zuwa firam ɗin da ke riƙe daidaitattun rollers. Ana iya daidaita wannan bisa ga kauri, faɗi da bazuwar tef, yadda ya kamata rage burrs akan gefuna na tef ɗin foil na aluminum. Hakanan za'a iya daidaita matsin iska bisa ga kauri na foil, musamman don kayan da suka fi kauri, yana rage haɗarin sharar kayan abu sosai yayin aikin iska.

Deburing tsari ne mai mahimmanci wanda ba za a iya yin watsi da shi ba, saboda burbushin da ba a kula da shi ba ko mara tsabta na iya huda takarda mai rufewa, yana haifar da gajeriyar kewayawa ko ma gobara. Kamfanoni da yawa sun jaddada mahimmancin wannan bangare.

Lura

Zane na musamman - na'urar lalata ta haɗa da uncoiler kuma tana iya motsawa a kwance don rage lalacewa da juriya lokacin ramawa don karkatar da tef. Wannan yana tabbatar da daidaitattun jeri na samfurin, yadda ya kamata yana kawar da datti a saman faren aluminum, kuma yana haɓaka kwanciyar hankali na ingancin samfur.

Na'urar walda ta atomatik: Wannan na'urar waldawa ta dace da buƙatun walda na filaye da jagora.

Don ɗaukar walƙiyar cinya, haƙarƙarin kayan walda na iya murɗawa zuwa wani matsayi.

Ƙananan muƙamuƙi na iya yin amfani da matsa lamba na sama kuma ana iya maye gurbin jaws kamar yadda ake bukata. An shigar da matsi na tsarin walda a kan fuselage, kuma bindigar walda, tsarin tafiya ta atomatik, da matsawa na iya motsawa hagu da dama a kan matse. Koyaya, da zarar aikin walda ya ƙare, injin walda yana motsawa baya zuwa hagu, yana sakin matsayi na iska don sauƙin aiki.

An ɗora bindigar walda a kan trolley ɗin hannu kuma ana iya daidaita shi zuwa wurare daban-daban don dacewa da nau'ikan walda daban-daban. Motar tafi-da-gidanka tana gudana ta hanyar motsi mai canzawa, mai ragewa da dunƙulewa. Ana iya daidaita saurin walda cikin sauƙi. Wannan hanyar walda tana amfani da madaidaicin halin yanzu da kai tsaye don waldawar argon (TIG) ba tare da buƙatar kayan filler ba.

Tsarin kula da lantarki: Tsarin sarrafa lantarki yana ba da umarni don abubuwa daban-daban na samarwa, kamar iska, daidaitawar karkatarwa, ƙidayar cinya da nuni daban-daban, dangane da lissafin tsarin kula da PLC ta amfani da shirye-shiryen tushen mu na mallakarmu da hanyoyin aiki. An tabbatar da aiwatar da tsarin daban-daban. Masu aiki kawai suna buƙatar shigar da sigogin aiki masu dacewa ta hanyar babban allon taɓawa na HMI don sauƙin kammala yawan samar da kayan aiki tare da ƙayyadaddun bayanai iri ɗaya.

Hakanan ana iya sarrafa duk kayan aiki da hannu ta maɓallan sarrafawa, gami da aiki nan take da aikin haɗin gwiwa. Akwai maɓallan gaggawa da yawa akan babban kwamiti mai kulawa da manyan kayan aiki. Lokacin da yanayi mara kyau ya faru, ana iya rufe tsarin cikin lokaci don tabbatar da aminci.

Ana iya yin duk ayyukan tsarin ta hanyar na'ura mai kwakwalwa ta duniya. Tsarin huhu: Tsarin yana ɗaukar iko na tsakiya da yawa da masu yin shiru don tabbatar da cewa matakin ƙarar injin gabaɗaya ya yi ƙasa da irin kayan da aka shigo da su. Za'a iya daidaita matsa lamba da yawan kwararar kowane reshe da kansa. Ana aiwatar da aiwatar da kowane aikin pneumatic ta hanyar shirin PLC.

Gida

Gida