01

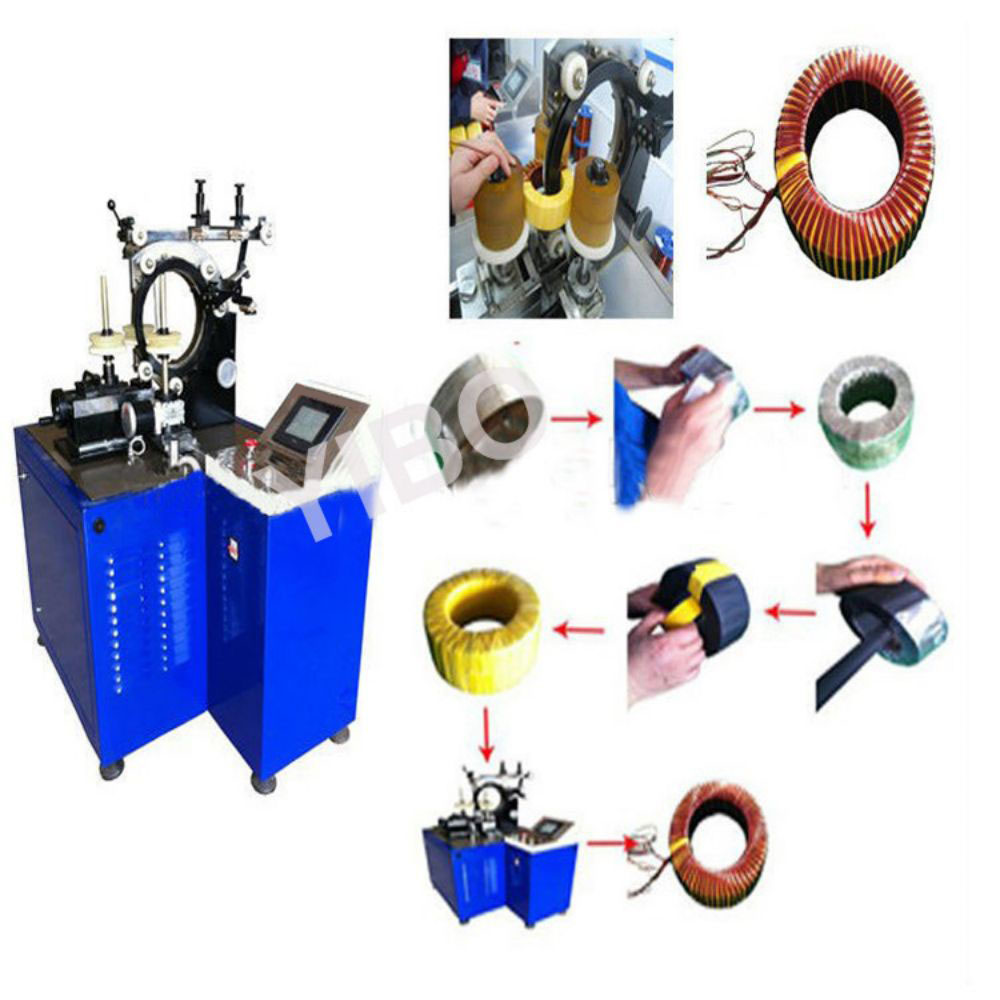

Advanced winding rauni core toroidal winding inji

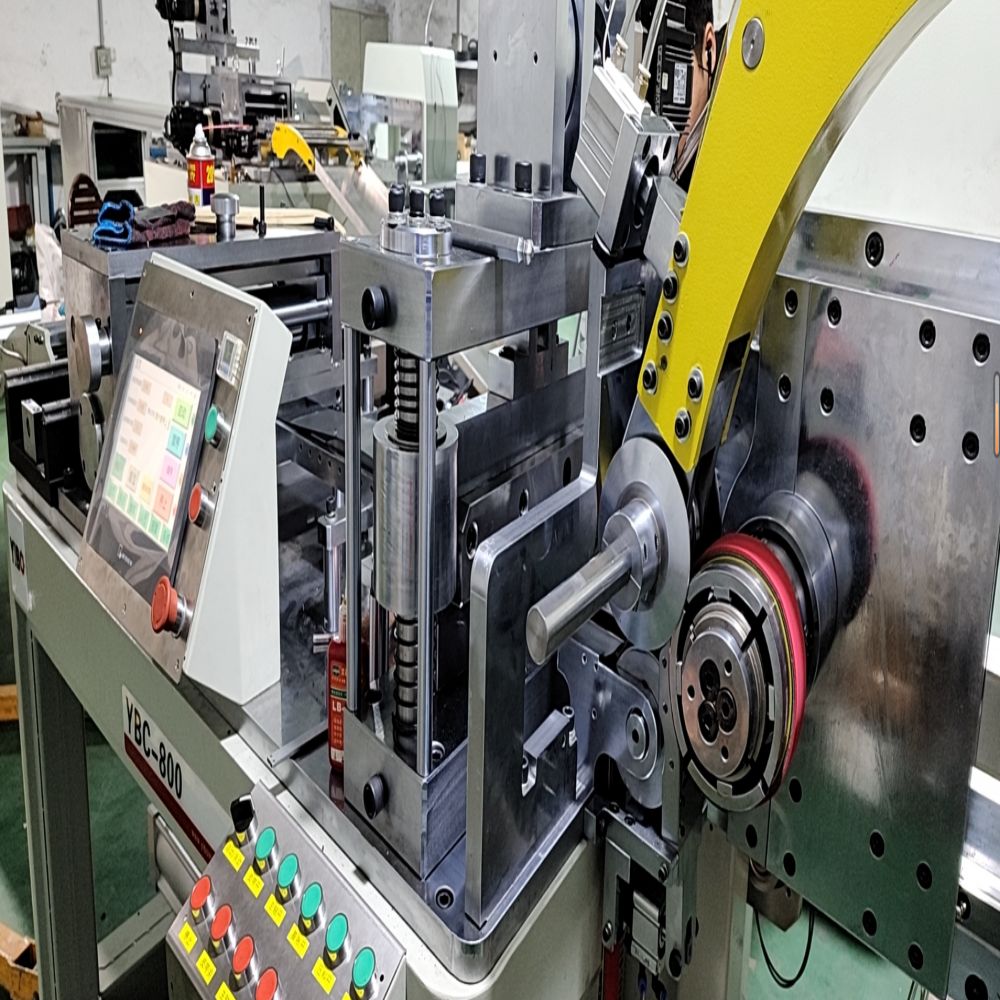

Na'urar tana dauke da sabon tsarin kwamfuta da fasahar tuki ta servo don sarrafa hadadden tsarin ciyarwa, yankewa da sake juyawa. Yana da damar sarrafawa da yawa, yana ɗaukar nisan tsiri har zuwa 250 mm kuma yana samun matsakaicin matsakaicin matsakaicin diamita na 800 mm. Na'urar tana ba da tsari mai sauƙi, daidaitaccen tsarin samar da abin dogara don masu rarrabawa. Ya haɗu da fa'idodi na asali na fasaha mai mahimmanci na rauni, kamar ƙarancin hasara mai ƙarancin gaske, taro mai sauri da babban kayan aiki idan aka kwatanta da babban jarin da ake buƙata.

Babban Siffofin

Cikakken aiki ta atomatik: Injin yana kammala ayyukan ciyarwa ta atomatik ta hanyar ciyarwa, jagora, iska, iska, da yanke ba tare da sa hannun hannu ba, yana haɓaka ingantaccen samarwa.

Tsarin sarrafa Siemens na Jamusanci da allon taɓawa na HMI: Na'urar tana sanye take da tsarin sarrafa Siemens na ci gaba da haɗin gwiwar HMI mai sauƙin amfani. Wannan haɗin gwiwar yana tabbatar da babban saurin ƙididdiga, ayyuka masu ƙarfi da sauƙi don aiki, sarrafawar samarwa mara kyau. Multifunctional toroidal core samar: Na'urar tana da ikon samar da raƙuman rata da aka rarraba da kuma toroidal cores don saduwa da buƙatun masana'antu da aikace-aikace daban-daban.

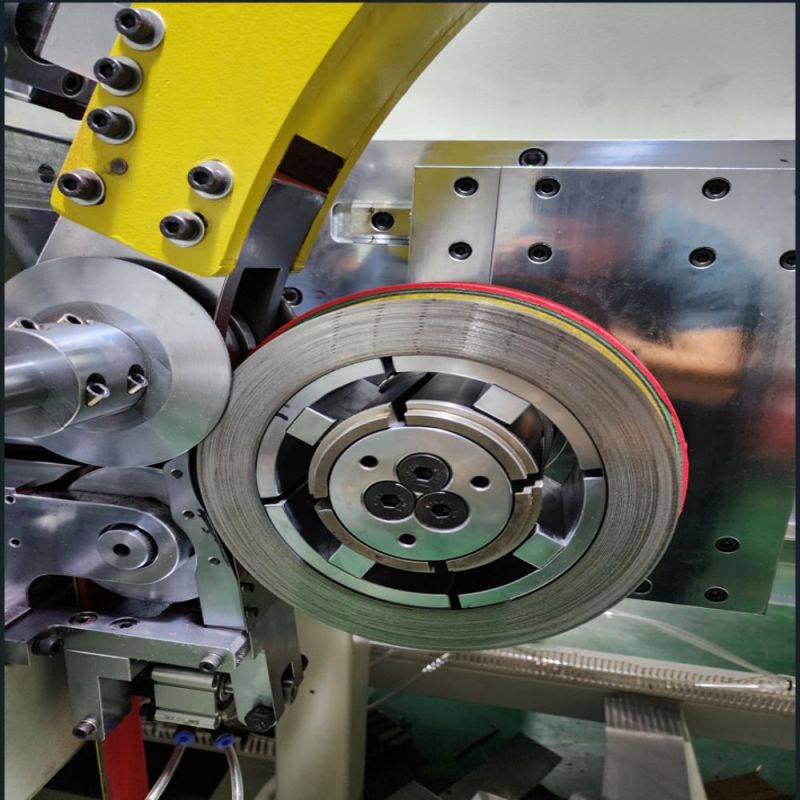

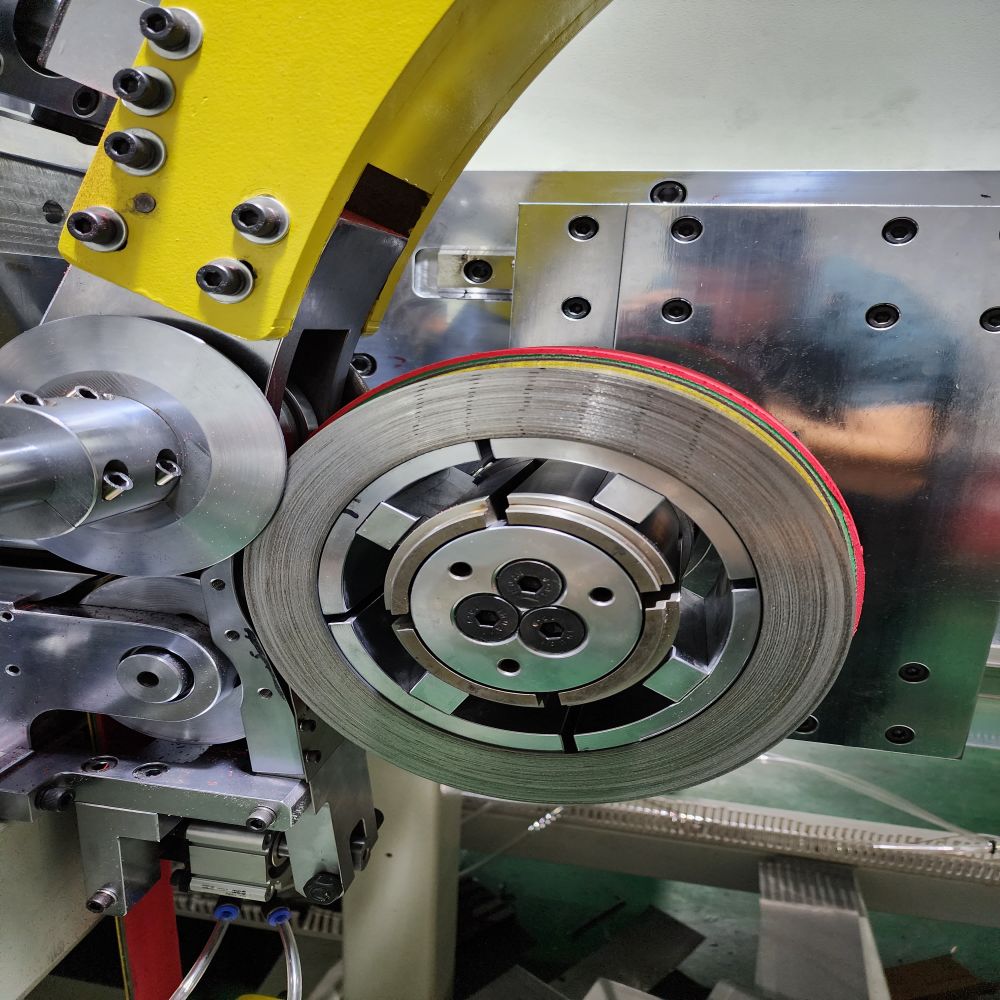

Matakai masu daidaitawa: Na'urar tana da ikon daidaita matakan tsaye daga 2 zuwa 15 don ɗaukar nau'ikan jeri iri-iri. Kowane mataki na iya ɗaukar zanen gado na asali 1 zuwa 3, yana ba da babban sassauci da daidaitawa don buƙatun iska daban-daban.

Daidaitaccen girman iskar gas da saurin ciyarwa: Masu aiki na iya sauƙin daidaita girman iskar gas da ƙimar ciyarwa ta hanyar haɗin gwiwar HMI mai sauƙin amfani, tabbatar da ingantaccen sarrafa tsarin samarwa.

Babban fasahar iska ta atomatik: Ɗaukar fasahar marufi mai sarrafa kansa yana rage buƙatun aiki da rage kurakurai, ta haka yana ƙara yawan aiki da ingancin samfur.

Ƙarfafa ƙarfi: Na'urar tana sanye da na'urar yankan karfe tungsten wanda ke tabbatar da ingantaccen ƙarfin aiki da rayuwar sabis koda lokacin aiki a ƙarƙashin yanayi mara kyau.

Abubuwan da aka gyara masu inganci: Injin yana amfani da kayan aiki masu inganci, gami da kayan aikin pneumatic na SMC na Japan da kayan lantarki na Turai da Japan. Yana amfani da injinan Siemens servo na Jamus, masu rage servo da aka shigo da su, jagororin layi, da bearings don tabbatar da kyakkyawan aiki da aminci.

Tare da rauni core toroidal winding machine s, za ka iya cimma ingantacciyar iskar iska da inganci. Ayyukansa na ci gaba, aiki mai sarrafa kansa da iyawar samarwa da yawa sun sa ya zama kayan aiki mai mahimmanci don samar da jigon rauni a masana'antu daban-daban.

Gida

Gida